Riding the plumbing roller coaster: Direction changes in a system give water a wild ride

Genuine father-son moments are rare and something both father and son keep with them their entire lives. This past summer, my son earned a free ticket to the big amusement park in our area for reading a certain number of minutes over a particular period of time. This meant some quality “man time,” as he and I call it, was in order. I have mentioned in past articles that my son tends to be on the timid side and this is still true. However, the young thrillseeker will get on a rickety old carnival ride if it seems to promise some sort of adventure. He is very tall for his age so, although he is only six, was tall enough to go on most of the roller coasters. An obedient husband would not have taken him on these roller coasters, but then there would be no story to tell.

As luck would have it, the simplest, tamest coaster that I wanted to start him off on was closed. Instead, his first coaster would be a rather fast coaster that I was hesitant to let him ride. But he insisted and, at amusement parks without maternal supervision, things happen. He got on without hesitation and rode it without fear. “That. Was. AMAZING!” he shouted when the ride was over; a moment I will never forget.

I will also never forget our final coaster of the day. It is ranked as one of the Top 10 scariest coasters in the world and, as I discovered, for good reason. This coaster is incredibly high, incredibly fast, and starts with a 90-degree vertical drop. Even as someone who loves roller coasters, I have never been more horrified. My son on the other hand, wanted to go again. This is when reason hit me for the first time all day and I directed him to rides that were less intimidating — to me.

When you look at what happens in a building’s drainage system, I imagine that the water and other media goes for the same type of ride that people on roller coasters do. As you race along the tracks, you encounter a number of changes in direction that designers and installers have to account for in order for the ride to flow smoothly, efficiently, and safely.

In a drainage system, the flow of liquid waste and sewage is constantly changing direction on its way to the public sewer or private sewage disposal system. Due to the laws of gravity, the flow in vertical piping will be much faster than the flow in horizontal piping of the same size. For efficient operation, it is necessary to make changes of direction in such a manner as to limit disruption of flow. There are provisions in the Uniform Plumbing Code for three possible conditions:

1. Flow from a vertical pipe into a horizontal pipe.

2. Flow from a horizontal pipe into a vertical pipe.

3. Flow from a horizontal pipe into another horizontal pipe.

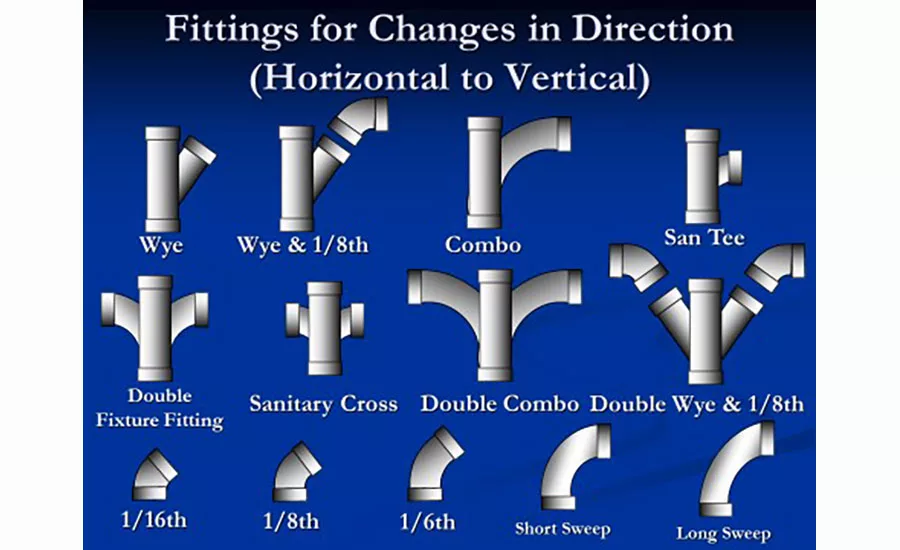

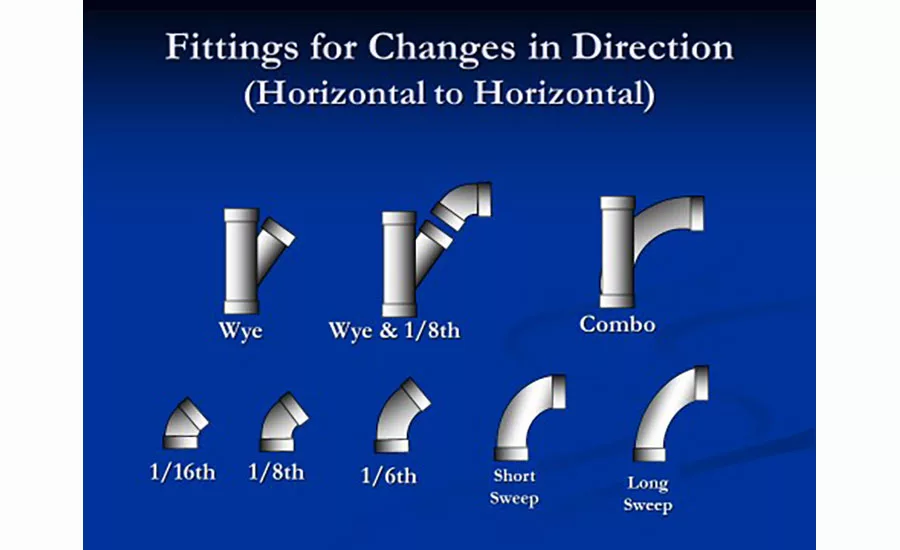

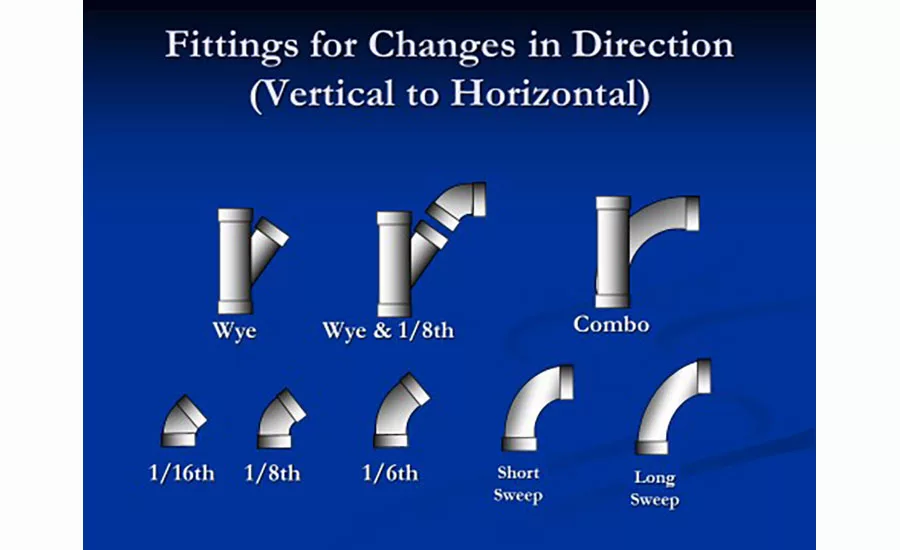

The chart in Figure A on the following page identifies the proper fittings to use in these conditions.

Horizontal to Vertical

A change in direction of drainage flows from horizontal to vertical creates an increase of velocity, which also increases the carrying capacity of the pipe at the point of transition. Therefore, short pattern fittings such as sanitary tees and quarter bends are permitted. However, there is a difference between the carrying capacity of short pattern and long pattern fittings. Tests have determined that long pattern fittings used to change flow direction from horizontal to vertical, such as a wye or combination wye and one-eighth bend, have twice the capacity of short pattern fittings. The downward sweep of a long pattern fitting reduces obstruction of air space and presents a smoother transition to annular flow (see Chapter 9, Section 907.1 for further discussion on vertical stack flows and pressure transients).

For two horizontal branches connecting to the vertical stack at the same level, a double wye or a double combination wye and one-eighth bend should be used. The downward sweep of the wye pattern directs the flow to the pipe wall below the opposite outlet opening. A double sanitary tee would direct the flow into the outlet opening on the other side of the fitting (see Figure B). However, a double sanitary tee could be used if the barrel of the sanitary tee is two pipe sizes larger than the largest of the two inlet pipes. The larger diameter of the stack allows a longer distance for the horizontal flow to arc across the diameter of the vertical pipe and to fall below the opposite outlet opening. Notice that one-half sizes are used for this purpose. Also remember that these are not fixture or trap arm connections; they are branch connections. Therefore, when Section 706.2 allows double sanitary tees to be installed, it is referencing branch-piping connections, not fixture fitting connections. For back-to-back or side-by-side fixture connections, see Section 704.2.

Horizontal to Horizontal

Unlike horizontal to vertical changes in direction, a horizontal to horizontal change of direction does not produce an increase in velocity, but tends to obstruct and diminish velocity. Hence, horizontal drainage lines connecting with other horizontal drainage lines shall enter through 45-degree fittings with as smooth and wide a turn as possible. Any interruption to the flow by short or abrupt changes of direction will cause turbulence and reduce the velocity of that flow. The adverse effects that could follow are pipes filling upstream from the point of transition, increased pressure changes within the drainage system, and insufficient velocity to carry away solids.

Vertical to Horizontal.

One of the most critical changes of direction from vertical to horizontal flows in the drainage system is at the base of a stack. As the vertical flow makes a forced entry into a horizontal pipe, the flow becomes violently turbulent and abruptly increases in depth downstream the vertical stack causing what is called a “hydraulic jump” (see also commentary in Section 901.2). This jump can cause backpressures upstream of the jump and affect trap seals in close proximity to the base of the stack. The proper transitional fitting with the proper sweep will reduce the affect of the hydraulic jump on the system. These fittings will be with 45 degree angles (wyes and combination wye and one-eighth bend) or sweeps (long and short). The short sweep fitting is not to be confused with a quarter bend fitting, which has a short ninety-degree radial bend. The short sweep radius approximates the radius of two one-eighth bends put together.

There is a lot of physics going on in a drainage system, especially with regard to changes in direction. While going from the fixture to the sewer may be a wild ride, the system needs to be designed and installed to properly make sure that the drainage roller coaster gets its passengers to their final destination in a smooth and efficient way.

"This article was originally posted on ww.reevesjournal.com."

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!