Ray Wohlfarth: The case for 2 psig

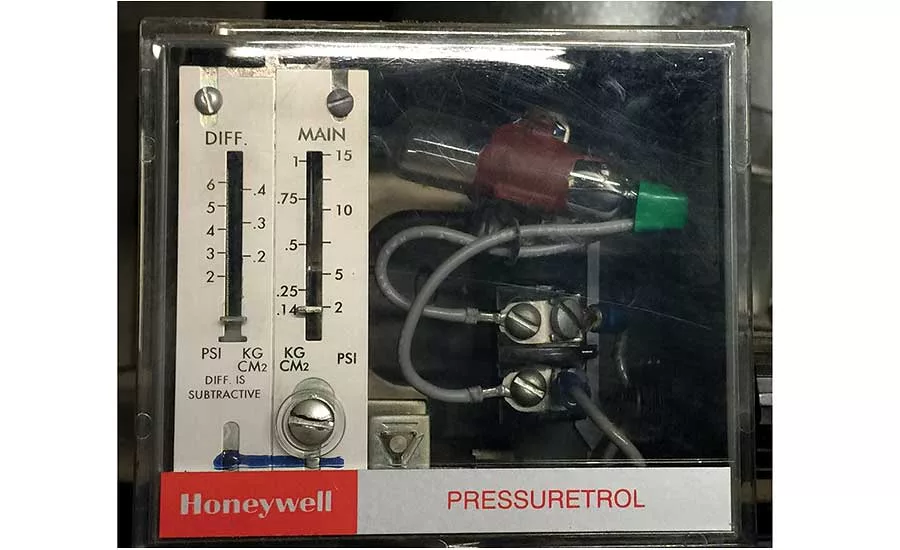

A pressuretrol controls when a steam boiler should begin and end firing based on pressure. Photo credit: Ray Wohlfarth

When I parked my truck outside the boiler room, I saw a thick plume of steam chugging from a pipe on the outside wall. Right away, my “Spidey Sense” started to tingle.

The maintenance director met me at the door, and we walked in. I was there to give him a price to replace the steam boiler. While walking through the boiler room, I noticed the black condensate pipe freckled with squares of red rubber gasket material held in place with hose clamps; an inexpensive way to fix a pipe leak.

On the floor by the boiler feed unit was a pair of old condensate pumps. Nowhere did I see any provisions for water treatment. While gathering nameplate data from the boiler, I saw the boiler was only 10 years old. The operating steam pressure control was set to start at 7 psig with a 2-pound additive differential.

My gut told me this was a room where boilers were sent to die.

Pressure

One of the questions I like to ask in my classes is, “What is the proper pressure setting for a comfort heating steam boiler?” The responses vary from 2 to 14 psig.

So, what is the proper steam pressure setting for a steam boiler used for comfort heating?

Ever since December 1899, the industry standard for low-pressure steam systems is 2 psig. When I tell the class the design pressure, many will look at me, disbelieving. I will then tell them the Empire State Building in New York City — at the height of 1,250 feet and 102 stories — uses 2 to 3 pounds of steam pressure to heat the building. I contend if they can heat a building that size with 2 to 3 pounds of steam, you should be able to do the same with your building.

Volume

While the system is cold and the boiler off, the pipes and radiators are full of air. On a call for heat, the burner heats the water until it becomes steam. When water becomes steam, the volume of steam is 1,600 times the volume of the water. It is like that expanding foam you use for sealing cracks, only much better.

For a steam system to operate correctly, the air has to be removed from the pipes and replaced with steam. Since the two gases — steam and air — cannot occupy the same space, steam at a higher pressure will push the air from the pipes through the air vents or traps.

Imagine your job is to fill a pipe with the least amount of balls and the only two options are ping-pong or tennis balls. Since tennis balls are larger, you would use fewer tennis balls than ping-pong balls to fill the pipe. When you have steam at 2 psig, the volume is 23.5 cubic feet. Think of this as a tennis ball. Steam at 7 psig is 19.9 cubic feet. This would be the ping-pong ball. You would need to generate 18% more steam at 7 psig than you would need at 2 psig to fill the pipes.

Boiling temperature

Ever since we were in primary school, we were taught the boiling temperature of water is 212° F. There should be an asterisk after that number, as water only boils at 212° at sea level and at atmospheric pressure.

Water boils at different temperatures at various pressures. For example, at 2 psig, water will boil at 218.6°. If the boiler pressure is 7 psig like this boiler, the water will boil at 232°, or 6% higher than at 2 psig.

Flash steam

If condensate is under pressure, above 212°, and is released into a pipe at atmospheric pressure, a certain percentage of the condensate will flash to steam. This flash steam adversely affects the efficiency of the system.

Flash steam was what I saw when I parked outside the boiler room. If condensate flashes to steam inside the condensate pipes, it could cause the system to stall and there would be comfort complaints. This is because the condensate pipes are sized for condensate and not steam.

Flash steam on commercial systems essentially wastes steam because the steam vapor is lost from the air vents on the condensate tanks. That lost steam results in fresh water introduced into a steam system which increases the possibility of scale and reduces the life of the system.

Condensate flashes about 0.67% at 2 psig steam pressure while at 7 psig, the flash steam percentage is 2.8%, or about 300% more.

Steam traps

Steam traps typically open once the temperature of the condensate drops 20° below the temperature of the steam. If the system steam pressure is 2 psig, the temperature of the steam is 218.6° which would make the condensate temperature about 198°.

At 7 psig, the steam temperature would be 232°. This would make our condensate temperature 212°, or the boiling temperature of water at atmospheric pressure.

Condensate return

When the condensate returns from the system, it has to be returned to the boiler. On commercial steam systems, this is usually done with a boiler feed or condensate pump. If the condensate temperature is above 212°, it could flash to steam and damage the pump.

In addition to the pump damage, the pump cannot pump steam so the boiler will go off on low water. I came across this disclaimer on a condensate pump:

“For best operation, condensate should be 160° F or less. Although <name of manufacturer> pumps can operate at higher temperatures, we cannot guarantee full capacity or satisfactory operation if condensate is allowed to go above 190°.”

Total heat

Many people feel that steam has to be set higher to get the heat they require. In process facilities, that may be true. If the system is for space heating, there is a small difference in heat between 2 and 7 psig. At 2 psig, the total heat is 1,153 Btu while there are only 4 more Btu when the steam pressure is at 7 psig.

If the system cannot heat the house or building at 2 psig, it is the system and not the boiler. You have to don your investigator cap and find the reason.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!