A lesson about PERT: Matching the appropriate materials to the proper application

The use of PERT materials provides flexibility and ease of installation for the application.

Polyethylene raised temperature-type materials have been used successfully in domestic hot and cold water piping systems for more than 20 years, and in application areas such as radiant underfloor heating and radiator connections, states a Dow Chemical report. The use of PERT materials provides flexibility and ease of installation for the application.

Hypertherm 2399 is primarily used for hot and cold water distribution systems and Dowlex 2344 is used for radiant heating applications. This allows for optimization of material properties targeted specifically for the particular application. To avoid compromising product design, the applicable PERT products are the product of choice in their respective applications.

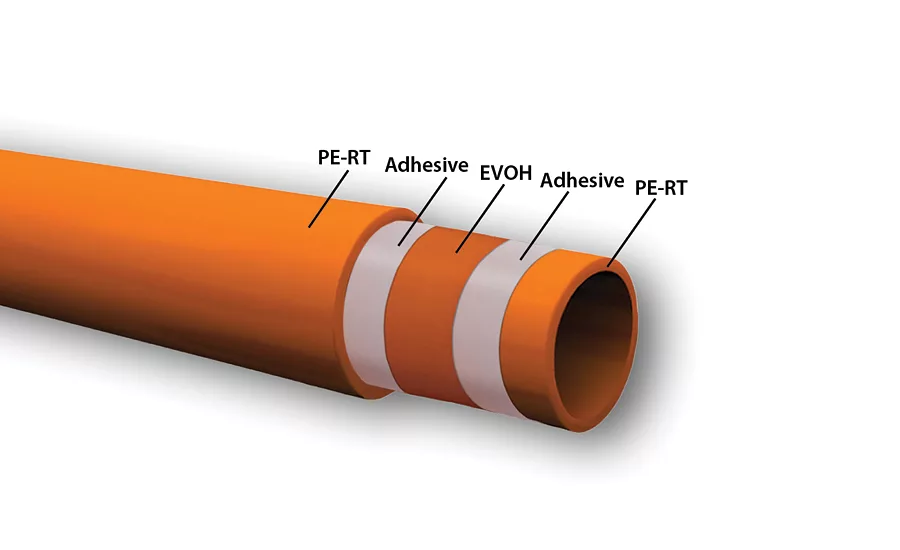

Dowlex 2344 resin is widely available in the United States and Canada in both five-layer (PERT/adhesive/ethylene vinyl alcohol oxygen barrier/adhesive/PERT) and three-layer (PERT/adhesive/EVOH) constructions to offer the widest possible choice in system design. The five-layered version gives the pipe strength.

This type of PERT piping includes: flexible, formable and pliable material; virtually leak-free performance; surface smoothness for improved flow with reduced pressure loss and deposit formation; and protection for the aluminum or EVOH layers in five-layer structures by inhibiting scaling and corrosion.

“Unlike BPEX tubing where the EVOH oxygen barrier is on the outside, exposing it to possible damage, the barrier is safely snuggled on the inside of the layers — protecting it from the elements, worksite conditions and the installation process,” says Michael Willburn, president of Infloor Heating Systems. “The five-layer tubing is more flexible and easier to install than other piping materials used in hydronic radiant heating, cooling, snow-melt, and distribution piping applications. The tubing is recommended for all nonpotable hydronic installation methods.”

Wolfgang Quack, from Dow Chemical, known as the father of PERT, worked together with Frank Hoepner, the owner of HPG Plastics, to develop the Dowlex 2344 resin. Paul Ross, president of Hydronic Alternatives, notes that the driving forces behind the invention of this product were installers in the field looking for a plastic heating pipe that was easier to handle and install than what was currently being used in the market.

“Dow Chemical has been very accommodating with us over the years to promote this new heating pipe to North America,” Ross says. “Pioneering our PEOC-Plus PE-RT pipe product against the grain and also with the stigma of polybutylene pipe still in everyone minds has been a challenge, but the results have been rewarding.”

He added that Dow’s introduction of Hypertherm 2399, made in the United States, presents “exciting opportunities for future growth in the plumbing sector.”

Zurn PEX also collaborates with Dow Chemical on its hy-PE-RTube barrier tubing.

“It offers the traditional benefits of polyethylene resin along with high-temperature resistance,” says Jeffrey Exley, Zurn product manager, water distribution. “Dowlex 2344 is recyclable and delivers long-term hydrostatic design strength at elevated temperatures, without the need for cross-linking — providing an economical and environmentally friendly choice when choosing tubing for radiant heating systems. This process increases the tubing flexibility, resulting in potential installation benefits and labor savings.”

The outer layer of Dowlex 2344 polyethylene resin provides a protective shield for the oxygen barrier, ensuring it remains intact. The five layers of this pipe consist of a layer of ethylene vinyl alcohol polymer sandwiched between two layers of adhesive and two layers of polyethylene copolymer resin. Ultimately this provides the radiant heat system with increased protection against oxidation due to piping permeation, safeguarding the system.

Watts Radiant’s RadiantPERT tubing also is manufactured with Dowlex 2344 and constructed with five layers. “RadiantPERT is certified to ASTM F2623 for PERT SDR 9 Tubing by NSF and CSA,” says Rich McNally, Northeast regional sales manager for Watts Water Technologies. “This standard includes requirements and testing methods for materials, workmanship, dimensions, sustained hydrostatic pressure strength and bend strength.”

Hot and cold water distribution

PERT tubing for use in hot and cold water piping systems uses a Hypertherm resin. Since the late 1960s when PEX was first developed, high-density polyethylene had to be cross-linked to make it strong enough to meet the requirements and standards for hot and cold water distribution systems. Using the latest technologies and innovative developments in HDPE, Dow Chemical continually improved PERT, culminating in 2012 when it patented Hypertherm 2399.

Hypertherm resins offer a smaller carbon footprint and enable the recyclability of monolithic pipe. Plastic piping has a longer lifespan than metal pipe and, with the resin, waste less water due to system design and leak-free performance.

“The resin offers differentiated advantages for hot and cold water pipe producers, homebuilders, contractors and homeowners,” says Carl Baker, senior development specialist at Dow Chemical Co. “It can run on the same extrusion lines as most types of cross-linked polyethylene, allowing manufacturers to have minimal tooling changes. Extruded pipe is ready for packaging directly off the line, requiring no post-extrusion curing. And it meets all U.S. building code and product standards.”

Piping made with Hypertherm 2399 can be joined with traditional mechanical fittings, he adds. It can be heat-fused for easier installation, and have better freeze/thaw performance than some other materials.

Pipe made with Hypertherm resin offers the following advantages over other commonly used plumbing materials such as copper and steel: flexible toughness; durable, virtually leak-free performance; resistance to corrosion and aggressive chemicals; ease of installation; little or no maintenance required; lightweight; and a reduced risk of theft (compared to copper).

“Hypertherm 2399 is made using bimodal technology, which gives it both strength and flexibility due to its molecular structure,” says Mike Boehk, senior product engineer at Legend Valve & Fitting. “Bimodal polyethylene technology is a two-reaction process that maximizes the creation of tie chains — which connect the crystalline structure and increase chain entanglement — by combining long chains at high molecular weight (strength) with optimal placement of short chains for lower density (flexibility).”

The company’s HyperPure pipe uses Hypertherm 2399 to meet and exceed ASTM F 2769, he adds. It has better burst and tensile properties, as well as slow crack growth resistance. Its flexibility allows it to lay flat, making it easy to handle, and it can be used with most PEX fitting systems. The pure part comes from no additives and no further processing is necessary; therefore, it remains a thermoplastic and is 100% recyclable.

“Whether it is for use in hot and cold water piping systems or in radiant applications, the attributes this piping provides can make PERT an attractive option for contractors,” McNally says. “With other piping materials, there is a limited lifespan, especially where aggressive water is present. Also, because the pipe doesn’t have to cross-linked, it is less expensive to make and therefore, less expensive for the contractor. It also offers corrosion- and chemical-resistance, benefiting the homeowner as well.”

Find out more about PERT tubing for plumbing and heating applications at these manufacturers’ websites:

-

CB Supplies, www.cbsupplies.ca/vipert

-

Hydronic Alternatives, http://tinyurl.com/HydAlt-PERT

-

Infloor Heating Systems, http://tinyurl.com/InfloorPERT

-

Legend Valve, www.legendvalve.com/pws

-

Roth North America, http://tinyurl.com/RothPERT

-

Watts Radiant, http://tinyurl.com/WattsPERT

-

Zurn Industries (barrier tubing), www.zurn.com

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!