Striving for hydronic ideals in heating systems

Let’s start with heat exchangers.

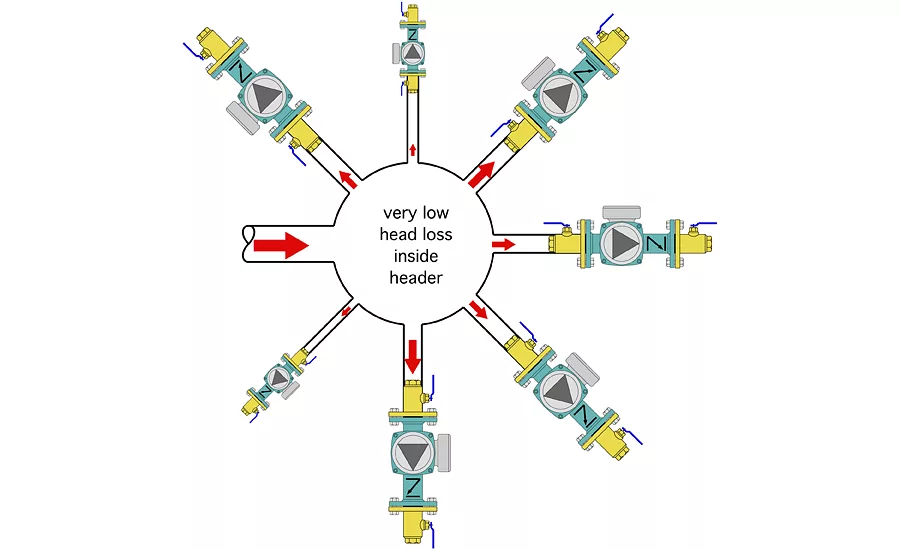

Figure 1. A single larger tube carries heated water into the copper basketball header. The concept is shown above. Graphics credit: John Siegenthaler

Figure 2. Select a pipe size that yields a flow velocity of only 2 ft. per sec. at the entrance of the header when all branch circuits are operating at full flow rate,Graphics credit: John Siegenthaler

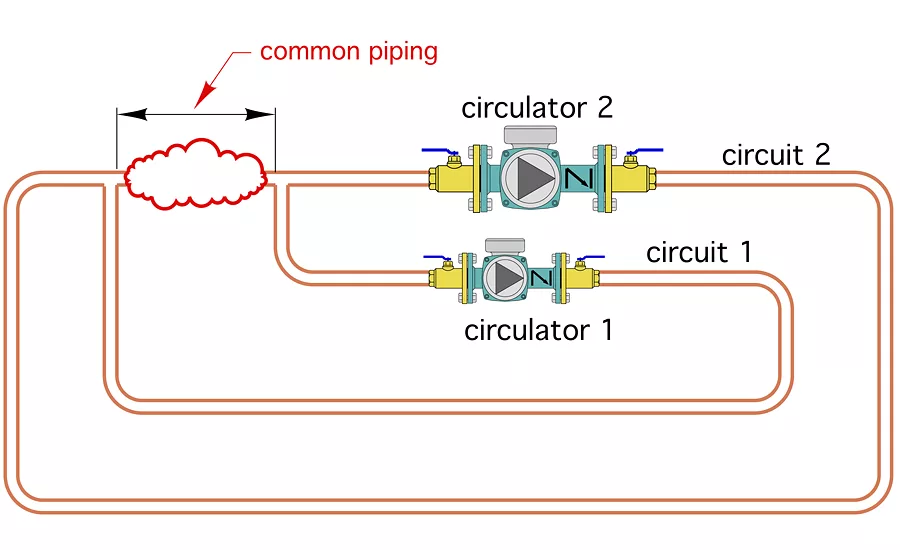

Figure 3. The common piping could be a pipe, a tank, a heat source, a pair of closely spaced tees, a collection of piping components or, not surprisingly, a device called a hydraulic separator like this one pictured. Graphics credit: John Siegenthaler

It’s also possible to build a combustion assembly/heat exchanger that has relatively low mass. Photo credit: Viessmann

It’s also possible to build a combustion assembly/heat exchanger that has relatively low mass. Photo credit: HTP

We live in a world where, for the most part, theoretical ideals can only be approached rather than fully realized.

For example, imagine a building with heat loss characteristics such that the rate of heat loss always matched the rate of internal heat generation from sunlight, people and equipment. Such a building would not require any heating system. Some of the new Passivhaus buildings approachthis condition, but still can’t guarantee that internal gains alone will always be sufficient to maintain comfort.

Even though many theoretical ideals cannot be fully achieved, it’s constructive to imagine them and drive our system designs toward them. Such an approach encourages the industry to strive for continuous improvement, higher efficiencies, improved reliability and smoother system operation.

Let’s take a look at several ideals, as well as design practices that move the systems we create toward these ideals.

Xchanged

Let’s start with heat exchangers. The “ideal” heat exchanger would have enough internal surface area to create a condition where the temperature of the heatedfluid leaving the heat exchanger is exactly the same as the temperature of the entering heatingfluid.

For example, imagine an antifreeze solution coming from a solar collector at 150° F. It enters a heat exchanger and transfers heat to a stream of water. The water leaves this ideal heat exchanger at 150°. Not 149.9°, but 150°. Such a heat exchanger would have a 0° approach temperature difference.

The good news is all the heat that could possibly be transferred from the antifreeze solution to the water would occur in this ideal scenario. The bad news is that this would require a heat exchanger with infiniteinternal surface area. That sounds pretty expensive.

Fortunately, it’s now relatively easy, using free online software, to select heat exchangers with approach temperature differences of 5° and in some cases even lower. The smaller the approach temperature difference between the incoming heating fluid and leaving heated fluid, the larger the heat exchanger has to be, and bigger heat exchangers cost more.

When selecting heat exchangers, designers should evaluate performance gains vs. higher cost over the full life cycle of the system. It often makes sense to go with a larger exchanger where the incrementally better performance results in the useful capture of millions, or even billions, of Btus over many years of operation.

By the way, an ideal heat exchanger also would have to operate with zero pressure drop on both sides, and remain free of any scaling or other fouling conditions that could degrade its thermal performance. Designers should approach these ideals by selecting heat exchangers for minimal pressure drop, and operate them with proper ancillary details such as demineralized water and devices that provide effective upstream dirt separation.

Short/fat headers

Here’s a question that probably has notkept you awake at night in contemplation: What would be an ideal hydronic header?

The answer is pretty simple: One that splits up the entering flow into the necessary branches while producing zero pressure drop and zero heat loss.

Imagine a “copper basketball” with tubing supplying several branch circuits sticking out of it in several directions. A single larger tube carries heated water into the copper basketball header. The concept is shown, at least two-dimensionally, in Figure 1.

The pressure drop within the copper basketball header would be very low, but not quite zero. If this header were well-insulated, it also could provide very low (but not zero) heat loss.

Now, imagine how unwieldy such a header would be to install in a typical mechanical room. Think about what it might cost to manufacture and ship such a header to a jobsite. Although its hydraulic and thermal performance would be very good, this design just doesn’t pass the practicality test.

The next best thing that would pass the practicality test is a “short /fat” header. One that minimizes rather than eliminates pressure drop and arranges the branch circuit connections in a row or two to make them compatible typical piping layouts.

How do you create a short /fat header? My suggestion is to select a pipe size that yields a flow velocity of only 2 ft. per sec. at the entrance of the header when all branch circuits are operating at full flow rate, as shown in Figure 2.

Selecting the header size based on this criteria might earn you some weird looks from installers who are less concerned about approaching ideal conditions or more concerned about tradition. But rest assured you’re providing a detail that conserves pumping power, and even helps contribute to good hydraulic separation of multiple circulators if they are supplied from the header.

Complete separation

Speaking of hydraulic separation, it’s a desirable trait in any hydronic system having multiple circulators that can operate at the same time. It’s also a pretty straightforward concept that we’ve discussed in many previous columns.

Good hydraulic separation is achieved by keeping the pressure drop in “common piping” that’s shared by two or more circuits, each having their own circulator, as low as possible. The common piping could be a pipe, a tank, a heat source, a pair of closely spaced tees, a collection of piping components or, not surprisingly, a device called a hydraulic separator (see Figure 3).

Perfecthydraulic separation would require zero pressure drop through the common piping, with all circulators running. It’s impossible to create such perfections. Fortunately, when it comes to hydraulic separation, almost perfect is good enough. Just identify the component(s) that will be the common piping, and make selections that keep the pressure drop through this portion of the system as low as possible.

A ballpark estimate is to keep the pressure drop through the common piping to less than 1% of that along any circuit connected to the common piping.

‘Treat your heat like lights’

That was a suggestion offered by Richard Watson at a Radiant Professionals Alliance conference held many years ago. He was describing the ability of very low thermal mass ENERJOY electric radiant panels, manufactured by Solid State Heating Corp., to begin releasing radiant heat almost the same moment they were supplied with electricity, just like most light bulbs emit light the moment they are energized.

It’s a simple but profound concept. One that arguably favors a very low thermal mass electrically heated panel vs. a typical current-generation hydronic radiant panel.

Imagine not having to maintain each room in a building at a normal comfort temperature just so you could be instantly comfortable if you happened to enter the room. If an instant output radiant panel could be created, the room could be maintained at a lower temperature when not occupied. This would reduce its rate of heat loss, and thus reduce the seasonal heating energy use.

A hypothetical hydronic heat emitter with no thermal mass could begin emitting radiant and convective heat the moment heated water passed into it. Such a panel could adjust its heat output to moment-by-moment changes in internal heat gains from sunlight, people and equipment. It would store very little heat when it’s time to put the space it serves into temperature setback. When the setback period ended, comfort could be restored instantly.

Again, we may never see a hydronic radiant panel with zero thermal mass, but panel radiators are now available that have less than 1% of the thermal mass of a 4-in.-thick heated concrete floor slab. They contain minimal amounts of water and metal relative to their heat-emitting potential. Such panels can thermally accelerate and decelerate very quickly to compensate for changes in internal heat gains. They are an excellent choice in modern highly insulated buildings that are subject to variable internal heat gains.

Boiler perfection

There are hundreds, perhaps even thousands, of different boilers now available for hydronic systems. They range from traditional high-thermal-mass cast-iron sectional designs to those with compact stainless-steel heat exchangers that hold less than 1 gal. of water.

So which end of this boiler spectrum is ideal?

The answer is neither.

In my opinion, the ideal hydronic boiler would have a zero thermal mass combustion system combined with a thermally isolated volume of water that could eliminate the need for a separate buffer tank. This combination also would have zero pressure drop and zero rate of heat loss to its surroundings.

About now you’re probably thinking that imagining such a boiler is a waste of time. But instead of dismissing what is arguably impossible, think instead about approaching these ideal characteristics.

It certainly is possible to build a device that holds several gallons of water in a very well-insulated enclosure. It’s also possible to build a combustion assembly/heat exchanger that has relatively low mass. Put them together into a marketable product and you will be close to that theoretical ideal. Such products do exist in both Europe and North America. Figures 4 and 5 show a couple examples.

Instant solar

A few years ago we installed a grid-connect solar photovoltaic system at our house. I’m inspired by how rapidly the output wattage of this array changes as the array goes into and out of shading by a cloud. For all practical purposes, the array responds instantly to changing solar radiation conditions.

This is not the case with solar thermal collectors. There are definitely times when a solar thermal system fails to turn on to grab what might only be a few seconds worth of available solar radiation shining down between passing clouds.

This happens because the collector’s metal absorber plate, and any fluid it contains, represents thermal mass that cannot be sufficiently warmed by a few seconds of solar radiation, at least to the point of activating a differential temperature controller.

But what if it could? What if someone created a solar thermal collector with an absorber plate having an extremely small thermal mass? Perhaps it would be built using carbon nanotubes or some other synthetic material that hasn’t yet migrated from the laboratory to the production line. What if the enclosure around that absorber plate approached zero heat loss, and the glazing above the absorbed plate approached a perfect transmissivity of 1.00?

Such a collector could grab short bursts of solar radiation and instantly transfer it to a fluid stream.

As with the perfect boiler, the ideal solar thermal collector can’t be built, at least not with the materials and technology currently available. However, the concept should give us pause to consider how changes to current collector designs might provide benefits. For example, could we build a collector absorber plate with less material or with far less internal fluid volume? If we could, the collector’s ability to capture short pulses of solar radiation between passing clouds would improve. A better-insulated enclosure would complement such an absorber.

Imagine if no one thought the Wright Brothers’ first airplane could be improved upon, or if it would be impossible to have a computer on a desktop much less on our wrist? What if no one in the early 1900s had envisioned an electrically powered circulator to move water through a hot water heating system, or had totally dismissed the future of hydronic radiant heating because some systems using metal piping embedded in concrete had sprung leaks?

The quest toward the possible starts by conceptualizing the ideal and moving toward it, often in small incremental steps. It’s my hope that future practitioners of hydronic heating and cooling will look back on what we do today as acceptable for the time, but far from the state-of-the-art at that future time.

Keep striving for the ideals.

This article was originally titled “Hydronic ideals” in the May 2016 print edition of Plumbing & Mechanical.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!