Two-pipe system

How to control such a system during the shoulder seasons.

|

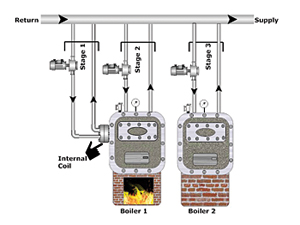

| Figure 1. Photo credit: Ray Wohlfarth |

A complaint building maintenance departments frequently hear is that the occupants are either too hot or too cold. In some instances, both complaints may come from the same room.

One of the systems with the most comfort complaints is a two-pipe system, which uses a supply pipe and a return pipe. In the heating season, the water in the pipe is heated with a boiler. In the cooling season, it is cooled with a chiller. During the peak of each season, this strategy works great.

The comfort complaints with this type of system come during fall or spring. During that shoulder season, the building may require heat in the morning and cooling in the afternoon. The complaints occur due to the dead band of the temperature difference between the lowest hot-water and highest chilled-water temperature.

Standard efficiency boilers are designed to operate above 140º F. Operation below that temperature could cause the flue gases to condense, which can destroy the boiler and chimney. Conversely, most chillers cannot operate with temperatures above 90º. (It’s always a good idea to check with chiller manufacturers as to their temperature limits.)

So, we have a temperature difference of 50º between the heating and cooling setpoint. You have heard that saying about how long it takes for a watched pot to boil, right? That is nothing compared to the time it takes for the temperature inside a two-pipe system to drop from the minimum heating temperature to the maximum cooling temperature on a mild spring or fall day. It may be anywhere from several hours to a full day and by that time, we may need heat again.

When a local school with a two-pipe system had to replace its boilers, it had several choices. It could use a condensing boiler that could handle lower water temperatures. However, the economics of converting the heating plant to a condensing system were more than the owner had budgeted.

Another option was to use standard boilers with a three-way valve that allows lower temperatures in the system. I am not a fan of three-way valves because they could lead to thermal shock of the boiler if not installed correctly.

Thermal shock can cause cracked sections or tube leaks. It is caused by a wide temperature swing from the return to the supply piping. Most boilers were designed to handle a 20° to 25º rise through the boiler. A three-way valve allows the water to bypass the boiler and be reset to a much lower temperature.

In many boiler control strategies, a one-to-one ratio is used. That means for every rise in outside temperature of 1º, the system supply temperature will lower by 1º. The typical reset schedule will range from 180º supply water at 0º outside temperature to 120º supply water at 60º outside.

At the low end of that reset schedule, the supply temperature will be 120º and the return temperature will be 100º. When that cool 100º water is returned back to the hot boiler filled with 160º water, rapid expansion and contraction happens. The boiler literally shakes itself to death. Remember the advice from Dr. Egon Spengler from the movie “Ghostbusters,” “Don’t cross the streams!”

Another drawback to three-way valves is that many boiler manufacturers require the installation of an additional pump, which will pull water from the supply and inject it back to the return to avoid shocking the boiler. To me, this is like driving with the parking brake engaged.

IECC regs

If your state adheres to the International Energy Conservation Code, a couple of regulations are required when controlling a two-pipe system. According to Section 503.4.3.2 of the 2009 International Energy Code:

• “... Systems that use a common distribution system to supply both heated and chilled water shall be designed to allow a dead band between changeover from one mode to the other of at least 15° F (8.30° C) outside air temperatures.”

A common setpoint arrangement is for the heat to be enabled below 50º and air conditioning enabled above 65º outside temperature. In between those two setpoints, most buildings use a combination of economizer operation for cooling and return air for heating.

• “... Provided with controls that will allow operation in one mode for at least four hours before changing over to the other mode.”

This may require some planning for the building owner to avoid complaints.

• “... Provided with controls that allow heating and cooling supply temperatures at the changeover point to be no more than 30° F (16.70° C) apart.”

In other words, the heating loop shall be no warmer than 120º if the chiller is designed for 90º entering water temperature at the changeover point. This is below the typical lowest operating temperature of most standard-efficiency boilers.

With all these things to consider, the school’s engineer and I put our heads together and came up with another system that works perfectly. One of the standard-efficiency boilers we used is a combination boiler with an internal coil, which was traditionally used for low-temperature operation such as domestic hot water water (see Figure 1). This internal coil could handle temperatures from 60º to 130º without risk of thermal shock.

This was our first stage of the heating system. It would handle the water heating during the shoulder times of the year. This allowed the loop temperature to drop to the 90º that the chiller could handle. As the reset schedule required warmer temperatures, the space-heating side of the combination boiler and the other boilers took over and supplied water up to 180º.

The benefit to the client is that this system can change from heating to cooling in less than an hour. The result is that comfort complaints are greatly reduced.

Read this article in pdf format.

HELPFUL LINKS:

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!