6 reasons why PEX excels in commercial hydronic distribution applications

PEX offers numerous jobsite benefits for commercial projects.

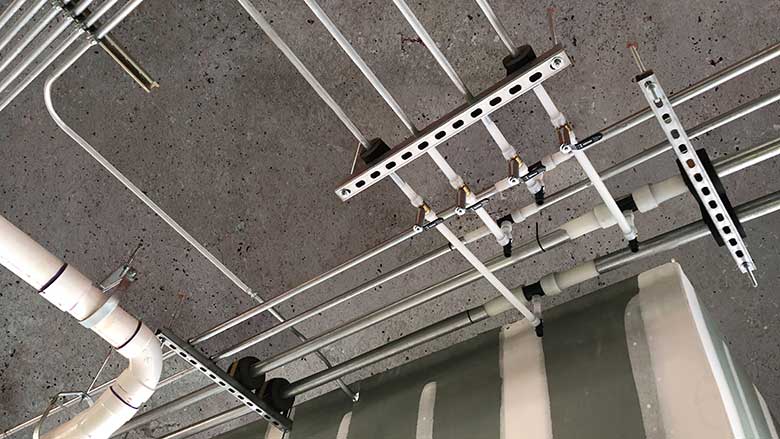

PEX resists corrosion, pitting, scaling, and rust, so it is much more durable in a hydronic system compared to metals. And its flexibility makes it much more resilient in freezing conditions. Photos courtesy of Uponor North America.

Historically specified and installed as radiant heating and cooling or snow- and ice-melting systems pipe, PEX is now trending as a viable hydronic distribution pipe for heating hot water and chilled water applications.

With sizes available up to 3 inches, engineers, mechanical contractors, building owners and even maintenance personnel are seeing the benefits of PEX compared to metallic piping systems, such as copper, steel and black iron.

From profitability to durability to job-site safety and productivity, this article will reveal how PEX beats metallics in all the critical areas of the commercial construction industry and highlight why it’s becoming the No. 1 choice for projects that need to meet tight budgets and schedules.

1. Profitability potential

Bidding a project in copper can be a gamble with price fluctuations in the market that change daily. Because PEX is not a traded commodity, the pricing is stable, making it much easier to effectively bid the job without a surprise spike in the materials costs when it comes time to purchase the product.

Additionally, flexible PEX is available in long coils. This makes installations faster and easier when installers can simply bend the pipe instead of having to stop and add fittings with each change in direction. Time is money in piping installations, and every minute counts when it comes to a large commercial project.

When installing PEX in suspended-piping applications, it’s important to know the hanging requirements. Using a galvanized-steel channel called PEX-a Pipe Support allows continuous support of PEX and enables hanger spacing similar to copper.

When installing PEX in suspended-piping applications, it’s important to know the hanging requirements. Using a galvanized-steel channel called PEX-a Pipe Support allows continuous support of PEX and enables hanger spacing similar to copper.

2. Job-site productivity

Speaking of “time is money,” eliminating unnecessary fittings adds significant productivity to a project. Some mechanical contractors have reported saving half the time installing with PEX compared to metallic pipe due to the labor savings of the flexible pipe. Also, because PEX is much lighter compared to metallic piping systems, it’s faster and easier for installers to move around the job site.

3. Job-site safety

A 20-foot stick of PEX is three times lighter than a 20-foot stick of copper. This means it is much easier to move PEX around the job site without potential back or body strain. It also reduces the need for heavy machinery to move it, such as forklifts and cranes.

Because PEX is not a traded commodity, the pricing is stable, making it much easier to effectively bid the job without a surprise spike in the materials costs when it comes time to purchase the product.

Because PEX is not a traded commodity, the pricing is stable, making it much easier to effectively bid the job without a surprise spike in the materials costs when it comes time to purchase the product.

PEX also eliminates the need for “hot work” on the job site. This means no concern or hazard with open flame for solder connections as well as no need for fire-watch requirements (saving on total project costs). PEX connections also eliminate the need for glues, solvents, and other potentially toxic materials that might be necessary with other connections, adding to job-site safety.

4. Workforce training

With the skilled labor shortage continuing to be a challenge, contractors need a piping solution that is fast and easy to learn. Flexible PEX requires fewer fittings, so installers don’t have to stop and make as many connections as they do with metal piping systems. Plus, when it does come time to make a connection, it’s much faster and easier to learn.

For example, the ASTM F1960 expansion connection method requires one simple tool that inserts into the end of the pipe to expand the pipe and an expansion ring before inserting a larger-diameter fitting. Installers can learn this method in a matter of minutes, and it also eliminates the issue of dry fitting (another bonus in the “reduced liability” section below).

The ASTM F1960 expansion connection method requires one simple tool that inserts into the end of the pipe to expand the pipe and an expansion ring before inserting a larger-diameter fitting. Installers can learn this method in a matter of minutes, and it also eliminates the issue of dry fitting.

The ASTM F1960 expansion connection method requires one simple tool that inserts into the end of the pipe to expand the pipe and an expansion ring before inserting a larger-diameter fitting. Installers can learn this method in a matter of minutes, and it also eliminates the issue of dry fitting.

Plus, some PEX manufacturers will come to your job site to train your installers, so you don’t even need to worry about training them. Simply schedule a time for the sales rep to come to your site, and you can have your installers up and running in no time.

5. Increased durability

PEX resists corrosion, pitting, scaling and rust, so it is much more durable in a hydronic system compared to metals. And its flexibility makes it much more resilient in freezing conditions. Because PEX can expand up to three times its diameter, it can accommodate frozen water in the system and then contract back down once the water thaws.

Additionally, a PEX hydronic piping system requires fewer nitrites, azoles and other chemicals to maintain a static hydronic environment, so the system is also easier to maintain. This not only adds to the system’s durability, but it also helps keep costs down.

PEX piping systems that use the ASTM F1960 expansion method eliminate the concern of dry fits, which means never having to worry if someone forgot to solder or cement a fitting.

PEX piping systems that use the ASTM F1960 expansion method eliminate the concern of dry fits, which means never having to worry if someone forgot to solder or cement a fitting.

6. Reduced liability

Because PEX resists corrosion, is more resilient in freezing conditions, requires fewer connection points, and is much lighter in weight compared to metallic piping systems, it greatly reduces liability. Furthermore, PEX piping systems that use the ASTM F1960 expansion method eliminate the concern of dry fits, which means never having to worry if someone forgot to solder or cement a fitting.

Also, because PEX not a traded commodity, it has no scrap value. Anyone who has been the victim of copper theft on a job site is familiar with this risk. PEX eliminates this concern, so you can rest easy knowing your materials won’t be walking off the job site, never to be seen again.

Important points to know when installing pex

For those that have never worked with PEX before, there are some key points to know prior to purchasing or installing the product.

Because PEX resists corrosion, is more resilient in freezing conditions, requires fewer connection points, and is much lighter in weight compared to metallic piping systems, it greatly reduces liability.

Because PEX resists corrosion, is more resilient in freezing conditions, requires fewer connection points, and is much lighter in weight compared to metallic piping systems, it greatly reduces liability.

Different PEX manufacturers offer pipe that is tested and listed to various regulatory requirements for installation in commercial applications.

Different PEX manufacturers offer pipe that is tested and listed to various regulatory requirements for installation in commercial applications.

All PEX is not the same

There are three different methods for manufacturing PEX that result in piping materials with different characteristics and durability. PEX-a offers the greatest flexibility, durability, and resilience in freezing conditions. Also, kinks can be repaired in PEX-a pipe with a simple shot of heat from a heat gun. This can save significant time and reduce liability when you don’t have to add in a coupling.

The other two PEX types — PEX-b and PEX-c — are slightly stiffer piping products that are not as flexible or durable in freezing conditions. They are not ideal for use with ASTM F1960 expansion fittings, and they are not kink repairable. So, these PEX types have potential to add liability on a project.

Know the codes

Different PEX manufacturers offer pipe that is tested and listed to various regulatory requirements for installation in commercial applications. Before beginning a project with PEX, make sure the product is manufactured, tested, and listed to the proper codes, standards, and listings for that specific application.

Hanger spacing requirements

When installing PEX in suspended-piping applications, it’s important to know the hanging requirements. Using a galvanized-steel channel called PEX-a Pipe Support allows continuous support of PEX and enables hanger spacing similar to copper. For ½" and ¾" pipe, spacing is every 6 feet. For 1" through 3" pipe, spacing is every 8 feet.

Expansion and contraction control

Using PEX-a Pipe Support can offer significant savings on hangers and supports and can also help control the natural expansion and contraction of PEX when it heats up and cools down. In fact, using PEX-a Pipe Support in conjunction with manufacturer-recommended installation practices can minimize the expansion rate of PEX to be equal to, or in some cases less than, copper pipe.

To learn more about PEX pipe and its different applications, check out these industry association websites at plasticpipe.org or ppfahome.org.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!