Minimize the risk of scalding

Scalding: What is it and why it should concern you

Courtesy of Migrenart / Creatas Video+ / Getty Images Plus.

Have you ever started your day thinking, “Ahh, coffee!” only to have it turn into “ouch!” as the steaming hot beverage hits the roof of your mouth? If so, you have experienced scalding. Luckily, the scald you experienced was (most likely) mild and, while quite painful, healed quickly and without the need for hospitalization or the prolonged medical treatment that is required for the nearly half a million people who experience scalding each year.

While spilling a hot beverage can cause scalding, it most often occurs when showering, using a hot water faucet, or immersion into a hot tub. Contact with a hot radiator — or other sources of steam and hot water — are also common commercial and residential sources of scalding. The potential for scalding is everywhere hot water exists!

While human error cannot be regulated, there is a way to minimize the risk of scalding. Minimizing this risk also can lead to reducing commercial liability. One method to reducing risk is to be in compliance with ASSE codes 1016, 1017, 1069 and 1070. These codes dictate the required protective valves to be installed on hot-water outlets for showers, tubs and faucets to greatly reduce the potential for accidental scalding. But before we continue, let’s look at what scalding is, and how it differs from a burn.

Leonard Valve’s Nucleus models give plumbing engineers complete system monitoring with outlet temperature control within +/- 2F from set point, regardless of demand. Features include user programmable set point, integral daily sweep and sanitization.

Leonard Valve’s Nucleus models give plumbing engineers complete system monitoring with outlet temperature control within +/- 2F from set point, regardless of demand. Features include user programmable set point, integral daily sweep and sanitization.

Scalding is defined as an injury to the skin that is caused by wet heat, such as hot water or heated oils, whereas a burn is caused by dry heat (like fire or a hot burner). Simply put, scalding can cause burns, but burns cannot cause scalding.

Another difference between a scald and a burn is the additional health and safety risks associated with scalding. The high humidity present during scalding opens the pores of the skin, allowing for quicker and deeper penetration of heat than with a dry burn. This can result in a more severe burn and increase the risk of infection. Water-borne bacteria that thrive in a warm, moist environment can enter through skin’s open pores, leading to a secondary injury in the form of a staph or strep infection, and resulting in painful rashes, additional blistering and even sepsis if the infection spreads to the bloodstream.

While all scalds should be treated seriously, not all scalds will require the same level of medical treatment. There are four levels of burns caused by scalding:

- Superficial epidermal: this is the type of scalding you are likely to experience from sipping that too-hot cup of coffee or worse, spilling it all over yourself. The scald hurts, and there is visible redness to the skin, but full healing of the skin occurs within a week or so, without medical treatment; the surface of the burned skin remains intact and dry, as there is no blistering. Rarely do such burns require time out of work or other loss of productivity.

- Superficial dermal: also knows as a “2a-degree scalding,” superficial dermal scalding is painful enough to require over-the-counter pain medication and bandaging, due to mild blistering of the skin. A 2a-degree scald usually takes two to three weeks to fully heal. The injured area should be rested, as movement can impede healing; time out of work or other loss of productivity may be required.

- Deep dermal/partial thickness: this type of scald is also called a “2b-degree scalding” and requires medical attention to limit the risk of infection. 2b-degree scalding is frequently less painful than less serious scalds because the epidermal layers of the skin and the nerve endings inside of them have been burned away. The skin does not blister (because the outer layers are dead) and instead looks dry and waxy, with a whitish or pale-yellow color. 2b-degree scalds generally take a month or two to heal and leave visible scars to the injured area. Time out of work and other loss of productivity should be expected. If the scalding incident occurred in a commercial environment, there is a strong possibility that a legal demand for compensation will be made.

- Full-thickness scald: more commonly known as a third-degree scald, a full-thickness scald requires immediate medical attention and can be life-threatening due to the high risk of infection, as the skin has been completely stripped, leaving muscle or bone visible. The burned area looks a dull white or brown in color and experiences no pain. Typically, the nerve endings have been completely destroyed. Full thickness scalding takes months to reach maximum medical improvement, and full recovery is not guaranteed. Heavy scarring will be present and permanent muscle contracture is frequent. If the scald is severe enough, skin-grafting or amputation may be required. Prolonged time out of work and lost productivity will be unavoidable. If the scalding incident occurred in a commercial environment, liability and damages are almost always sought by the burn victim, and financial awards can be in the millions of dollars.

Complying with ASSE 1016, 1017, 1069 and 1070 will drastically reduce the odds of scalding occurring in the first place, thus mitigating the risk of injury to others and your risk of commercial liability.

Complying with ASSE 1016, 1017, 1069 and 1070 will drastically reduce the odds of scalding occurring in the first place, thus mitigating the risk of injury to others and your risk of commercial liability.

When it comes to scalding, prevention is the best medicine! Complying with ASSE codes 1016, 1017, 1069 and 1070 will drastically reduce the odds of scalding occurring in the first place, thus mitigating the risk of injury to others and your risk of commercial liability.

The easiest and most reliable ways to comply with ASSE 1016, 1017, 1069, and 1070 codes are through master mixing valves and point of use (POU) Valves. The most basic master mixing valves control water temperature by using paraffin or liquid wax, or bi-metal thermostatic coils, all of which expand in the presence of heat and contract in its absence. The valves will open or close at the introduction of hot or cold water, creating a “Goldilocks zone” where the water temperature remains in a “just right” range that human skin can tolerate.

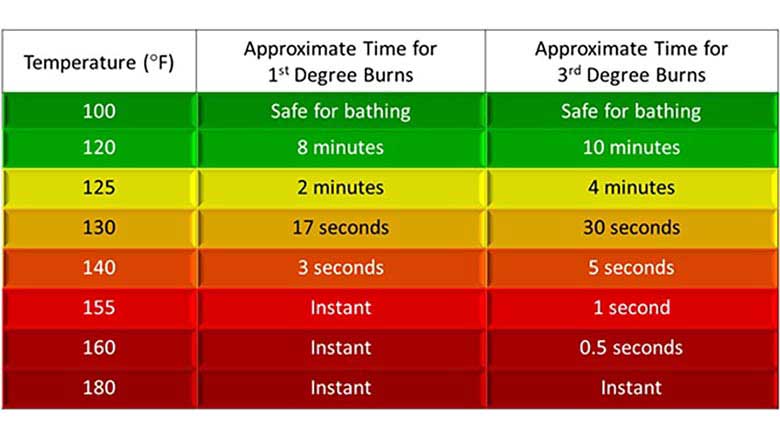

Chart courtesy of Leonard Valve Co.

Chart courtesy of Leonard Valve Co.

Within the last ten years, a new type of master mixing valve has come on the commercial plumbing scene: digital master mixing valves. Digital master mixing valves offer a variety of safety features, including tighter temperature controls (within ± 2° F, instead of the traditional ± 7° F max), and the option to electronically lock in a temperature range so it cannot be altered without a passcode. In the event of cold-water failure, digital mixing valves can stop the flow of hot water instantaneously. Digital master mixing valves can also be utilized as a “connected device,” allowing for the constant monitoring of temperature and come with available “cloud” storage and industrial data-management systems for exacting record-keeping of safety-code compliance. Digital master mixing valves are self-balancing, and most are self-cleaning, making for easy installation and minimal maintenance.

When it comes to scalding, prevention is the best medicine! Complying with ASSE codes 1016, 1017, 1069 and 1070 will drastically reduce the odds of scalding occurring in the first place, thus mitigating the risk of injury to others and your risk of commercial liability.

In addition to master mixing valves, the small but mighty POU Valve (also known as a 1070 valve) acts as a final temperature checkpoint before water exits the outlet and onto the user. Designed to all but eliminate scalding, a POU valve works by compensating for both hot and cold water pressure fluctuations. These valves ensure that the water outlet temperature doesn’t exceed 120° F. Upon cold-water failure, the POU valve will shut down the hot water supply (to ≤ 0.2 gpm) before the water temperature reaches 120° F.

In the U.S., 35 states legally require compliance with ASSE 1016, 1017, 1069 and 1070 codes in commercial building projects, through the adoption of the International Plumbing Code. Standardized in 1995, IPC codes are “provisions consistent with the scope of a plumbing code that adequately protects public health, safety and welfare; provisions that do not unnecessarily increase construction costs.”

With IPC code compliance as your guide, and the safety features added by installing digital valves, the odds of being held commercially liable for scalding injuries drop to as close to zero as possible. When we put safety first, everybody wins!

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!