Backflow prevention: The last line of defense for plumbing system safety

Backflow testers hold one of the most important roles in safeguarding water supplies.

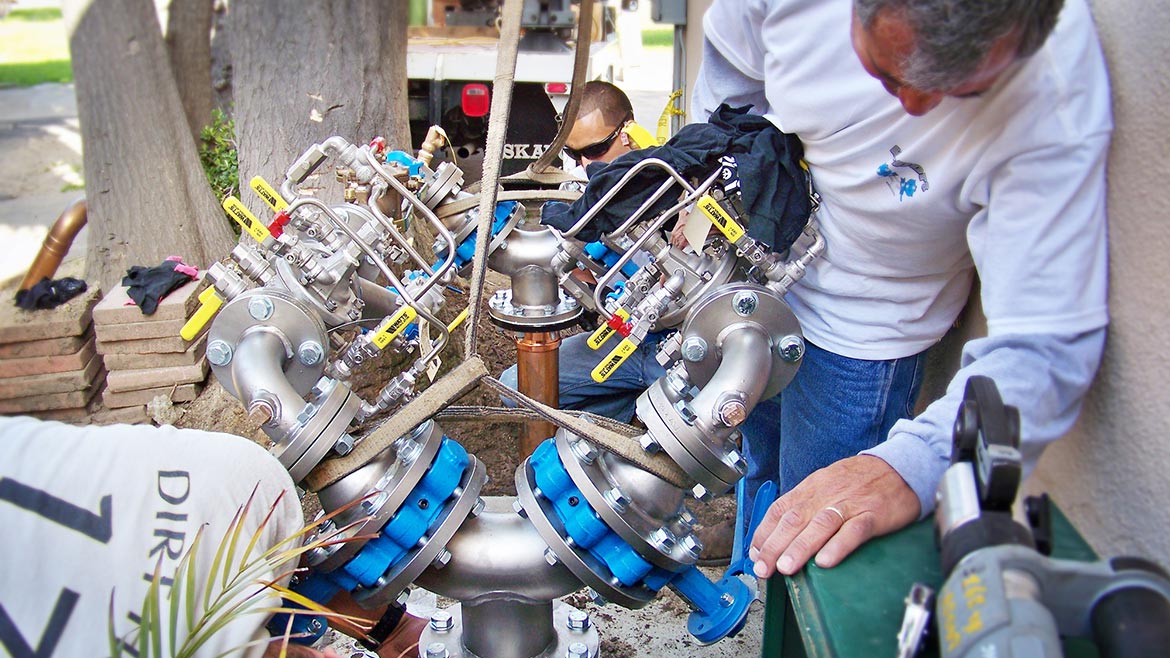

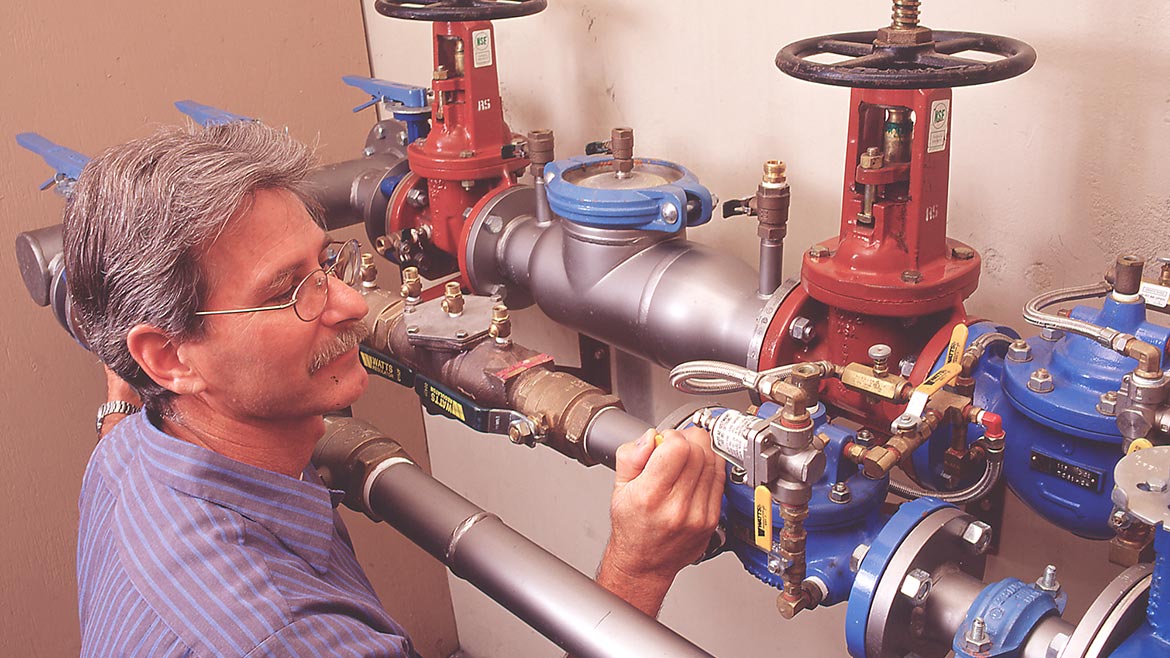

Dave Yates performs backflow testing at a factory's fire sprinkler system (glycol in the line). He's testing the pressure differential across the assembly's check valves.

Even as war rages in Europe and economies struggle against food and raw material shortages and exploding inflation, human populations, worldwide, are still mired in the risks posed by COVID-19 and its many, post-pandemic viral mutations.

Two facets of building infrastructure have gained close attention in the wake of widespread disease: Indoor air quality and water quality within commercial structures. Adding to the problem of providing clean water, globally, are challenges posed by an aging municipal and commercial infrastructure.

The threat of contaminated water is one of the hottest issues in the water distribution business today — whether you live in York, Pennsylvania; York, Wisconsin; York, England; or York, South Africa. For the most part, technology, technique and testing control the problem, though, as aging municipal and commercial water systems are pushed to fulfill their role, the links in our once sturdy chain weaken and are at greater risk.

One of the most important roles in safeguarding water supplies is that of the backflow tester. In many respects, it’s their role to verify system safety at the most critical link, the backflow assembly, designed to protect drinking water supplies from contaminants.

Rules of engagement

To protect itself from liability claims, and its customers from the potential of catastrophic accidents, experts generally agree that a water company’s backflow prevention program should be written with all specifics articulated and fully enforced. Certain checks and balances for customers and testers become the rules of engagement.

“A stand-alone policy needs to specify how a test is to be conducted and submitted to the municipality, as well as give the municipality the ability to enforce its rules with both the owners and testers,” says Cameron Rapoport, a backflow product specialist with Watts. “This way, municipalities can ensure that assemblies are both being tested and tested properly.”

The danger within

By design, water is expected to flow in one direction within piping systems — from the water supply to the point of delivery. Any time pressure in the system drops, even momentarily, the system can be subjected to backflow, through either backpressure or backsiphonage — opening the door to sources of contamination. This can happen all too easily when a water main is shut off, broken, or water demand surges in a specific area.

Ultimately, it’s rigorous backflow prevention and competent, thorough testing that guards against the possibility of cross-contamination. System designers and testers of these complex piping systems know the importance of eliminating potential cross-connections.

“But this goal has its challenges,” Rapoport explains. “Especially when we consider the vastly more complicated connections to water at user sites such as medical and diagnostic centers, research facilities, exterior fire sprinkler systems with glycol antifreeze and recycled water carwashes, just to name a few.”

Bernie Clarke of Clarke Sales, Valencia, California, who has been recognized as one of the Southern California area’s top backflow experts for years, says the weak links in the chain are: Inconsistent accountability to agencies of jurisdiction; insufficient training of testing personnel and — too often — lack of experience when handling anything out of the ordinary; loose requirements for testing procedures; and a cross-connection control (CCC) policy without specific needs or demands for the water company above minimum standards, permitting far too much flexibility.

“All can lead to serious challenge,” Clarke says. And, if combined, it’s a near certainty that problems will occur. The key answer to these problems is for water companies to set a baseline for testing performance and verification, and to enforce them.”

Verifiable accountability

One challenge today is that there are so few standards for verifiable accountability of the testers. In south-central Pennsylvania, very little is asked of the tester, and there are few requirements for ‘witness stamps.’ Nationally, most backflow test forms simply require a signature. There’s room for improvement.

There should be verification of the tester’s presence at the valve. Also, OSHA guidelines for confined space entry are dangerously ignored by many testers.

Locally, the York, Pennsylvania Water Co. changed its backflow testing protocol several years ago, incorporating important improvements. They’d always required yearly recalibration, so that wasn’t the issue. But, they recently added a line for on-site witnessing, meter reading and would occasionally conduct surprise spot checks to observe tester in action — all good things.

In the York, Pennsylvania area, I personally tested more backflow preventers than all other testers combined [Yates]. In my opinion, one of the worst dangers when performing these tests can happen during confined space entry. It’s not uncommon for backflow assembly pits to have deficient oxygen levels and, in my experience, I’ve encountered a few that registered zero oxygen! We called those the “widow-makers.”

Therefore, it’s important to ensure that all employees having any involvement in backflow testing are OSHA certified.

A recollection from one large job illustrates the point nicely: When we were doing a huge snow-melt project at WellSpan York Hospital, they commissioned new concrete vaults for us to install the snow-melt distribution manifolds. One day, the facility’s jobsite supervisor said our work had to stop until we all received OSHA confined space certificates for our work in the pits. Our team immediately presented him with a copy of the OSHA certifications, showed him we were testing the air quality, were properly harnessed and that topside employees had full authority for controlling the immediate vicinity of our confined space entry. End of issue. Mic drop!

But I [Yates] still wish the protocol would be more rigorous. Such as: A policy or guidance document that verifies the tester’s presence and establishes that all backflow components are functioning properly. Also, a main water meter reading, and a facility representative’s signature as witness if meter-reading requires confined space entry, and time of day.

Managers of York Water Company (YWC) knew, as did many of those who conducted BFP tests professionally, that there were far too many cheaters filling out the test forms. When accredited testers go through certification training, they learn what the expected results are for the pressure differential readings across the checks and at what PSI the relief should begin opening. YWC added additional requirements, including water pressure, meter reading and surprise inspections to test the testers, to make it tougher to cheat the system.

One example of cheating comes to mind: A new customer — a very large printing press operation whose backflow preventer was said to be in a pit (meaning confined space entry) — said the test had to be performed on a Saturday at a specific time because some of the large tractor-trailer-sized presses were water-cooled. Time would be of the essence because the crew would be interrupting their operation.

However, what appeared to be the BFP pit when the manhole cover was pulled was a brass non-testable swing check valve! The maintenance guy said that it was, in fact, the pit the other plumbers had used to test the backflow . . . and produced his copies.

We explained that nothing about it was as it should be, then asked if he knew where the water entered the building. He took us through expansive rooms and halfway through the plant before we spied the three-inch backflow preventer, an RPZ. According to the maintenance guy, it had never been tested! Imagine an RPZ in the middle of a factory that prints things like baseball and football cards. Consider the potential liability if there would be an uncontrolled discharge at any time a tester was present at the RPZ. We rescheduled the test for a time when factory personnel could arrange to have all of the printing materials removed from that area.

The testing went off without a hitch, and water from the relief zone was able to be captured and contained. That became a huge embarrassment for the other plumbing companies that had previously worked for the large printing firm, and F.W. Behler won the stars, and a long-term customer.

What’s to be done? Where to begin?

Water pressure is a very important factor and should be noted on the test form that polices the CCC program. These key facets apply:

- In some areas, water pressure can be excessively high. This places a lot of stress on the backflow device and, by the way, if pressures are above the rated working pressure of the assembly, this will negate a manufacturer’s warranty; and

- The customer should be informed if the pressure is regulated, or not. The pressure regulator is a key component of safety to the water piping system.

The tester must come in contact with the valve to get the pressure reading, and data recorded that verifies this.

Requiring a water meter reading forces intelligent contact with the backflow assembly. The tester must verify what water meter he or she is shutting off prior to the test. The water meter reading should provide when the unit was actually tested. The water meter reading also helps to police the program. A key advantage is that the water company can see how much water went through a meter if a tester’s results are re-tested or verified.

Unauthorized connections are important. If a tester is going to be at the backflow assembly, then have the tester verify what you want him to see and look for, and to note it on the form. If there’s a stipulation that unauthorized connections be looked for, it’s rather amazing what problems can be averted.

Gauge calibration should be in the policy. When testing behind a tester, it’s important that both gauges be accurately calibrated. If so, the only remaining sources of inaccuracy are technique, test procedure or erroneous recording.

Verification of forms and data helps to focus the tester on getting the job done. It also tells the water company when the form was ready to be released to the tester. Other advantages include: Dates provide a tracking record, and testers know when they must complete the test and return the form to the water company; the owner/agent can’t say they never got the form because they would need to sign and date it, confirming receipt and review of the information; and the water company receives a validated test form just as it was validated by the witness stamp (with signature and date).

Check valve #2 is tested by the two-hose method (tc3 and tc4). Much more accurate and revealing of actual component’s condition, this method offers so much more than a simple back pressure test. And it places specific requirements of the tester with results that can be reviewed and verified. The widely accepted back pressure test does not reveal what springs are in check #2, for instance. Thus, a tester would put his stamp of approval on a backflow assembly that could potentially have two #1 springs installed. The two-hose test is highly sensitive analysis of disk and spring condition, showing their ability to seal and contain backflow pressure. It’s also unforgiving: Dirty conditions within the valve or weak or broken springs will be ferreted-out before troubles begin.

Plumbing, irrigation and fire system specifics should be noted. This adds valuable context to the tester’s actions. Before water service is turned off, the tester acknowledges what the backflow assembly is attached to, and (hopefully) considers the impact of his or her immediate actions. And, of course, some information about the system should be noted on the form.

There is value to data that simplifies customer ID. Alpha-numeric identification (e.g.: APR007-DEC121-F), can show date, what device is being serviced and is a quick reference to test due dates. It becomes a very sensible way to sort forms with easy combinations of information of value to you. Coding within the number, for instance, might use F for fire, D for domestic and I for irrigation.

Perfect storm

RPZ type backflow preventers integrate a differential pressure relief valve that senses pressure imbalance across the first check and opens if that differential falls below a setpoint.

“This integrated safety feature ensures that potentially contaminated water is discharged into a drain or sump rather than be allowed to flow back into clean water sources,” Rapoport explains.

According to Rapoport, the relief valve also serves as an indication of a fouled first check, causing the relief valve to discharge. While this provides visual indication of failure — an important feature for a safety device — the valves are often in areas where discharge won’t be noticed, a challenge that could lead to property damage. A related problem could be insufficient drain size or, worse, no accommodation for drainage at all.

This “perfect storm” of challenges has led to the first major digital technology backflow preventers have brought to market — flood detection and protection devices.

These devices sense relief valve discharge, which activates an alert to users, allowing them time to address the condition before it worsens or causes damage or, better yet, can automatically shut off the water supply. Given that relief valve discharge from a 3-inch RPZ backflow preventer can reach up to 500 gpm, it’s easy to imagine the need for these protective measures.

Imagine the potential discharge from a backflow larger than 3 inches! But, even with sudden discharge from a 3-inch assembly — and a confined space, like a pit — that would present a real danger of engulfment. A torrent of water with that sort of volume would almost immediately restrict an exit from the pit. Many deaths have occurred due to engulfment.

This is why testers need to be OSHA-certified for confined space entry, and to conduct testing in strict compliance with the OSHA regulations. Just the danger of engulfment is reason enough to mandate certification.

And, on the financial side of things, the average commercial flood claim is $75,000 to $100,000, but can easily reach over a million dollars, especially when a discharge occurs at night or on the weekend when water damage may be left unaddressed for hours, or days.

New technology to the rescue

The flood alerts available to the customer vary by provider, but can include text, email and a phone call. The connection is also important. Commercial building operators are reluctant to allow a device not controlled by their IT department access to their Wi-Fi networks. So, even if a product requiring Wi-Fi access is installed, it’s unlikely to be connected and registered. Devices that operate through a cellular connection, however, may be greatly more appealing to building owners and operators, even if there is a nominal fee for the service.

These devices communicate with an automatic shutoff valve. This is a form of Automatic Control Valve (ACV) that uses a diaphragm and a small solenoid to shut a valve. The advantage of using such a valve, as compared to something like an actuated gate valve, is that you don’t need an expensive actuator that might require a 240V power supply. By using a diaphragm, these valves need only a small solenoid in order to shut down even very large valves.

Automatic shutoff isn’t needed for every application. Hotels and hospitals, for instance, typically won’t want the main water supply shut off automatically, even if it is to prevent a potential flood. However, other businesses or applications may greatly benefit from automatic shutoff. One example is a backflow supplying a chiller on the roof. It will likely be in a mechanical room on a high floor, the perfect scenario for substantial water damage.

Flood detection and protection is the first real foray of backflow preventer manufacturers into making their valves smarter and connected to the internet, but what about testers?

Even backflow testing has entered a new, innovative dimension. While testing has largely been performed the same way for decades, the recording and submission of test results have evolved substantially.

Backflow testing used to be an arduous exercise with loads of paperwork. Testers and water purveyors could spend 20% of their time dealing with test reports and submittals (or submittal entries) ¬— making sure they were filled out with all the necessary information, dealing with different test forms for each municipality and submitting it through any combination of mail, fax and email.

These challenges are wasteful and costly.

Backflow test management software now helps to automate redundant data entry such as tester ID and credentials, test kit calibration, etc. They can even help keep track of previous tests, auto fill forms and help the tester reach out to previous customers when they know their next backflow test must be completed. Many testers are independent or part of a small company, so this can be a huge step forward in productivity. Water purveyors are also beginning to adopt software to better manage their backflow test reports.

Test management software can also help simplify the test itself. Backflow test forms can be confusing because they squeeze all the required tests onto a single sheet. RPZ, DC, DCDA, RPDA and PVB tests all have to compete for space along with other required information for the tester and valve. Adding to that challenge, many municipalities have a different variations of the form. Test management software can eliminate all the wasted space so all you see on a phone or tablet are the fields that need attention.

Though the backflow prevention industry has been slow to adopt digital technology, products are coming to market that provide real value. Manufacturers and other companies in the space will continue to innovate to help make our water safer and cleaner.

Selecting a backflow preventer

The type of backflow assembly to be used varies according to the type of substance that may be at risk of flowing into a clean water supply. A “pollutant” may be any substance that would affect the color or odor of water, but would not necessarily pose a health hazard. A true health hazard exists when a substance or contaminant, if ingested, could cause illness or death.

System hydraulics is the second factor to consider while selecting a backflow assembly.Hydraulics mandate whether a backsiphonage, backpressure or a continuous pressure device is needed.In the case of backsiphonage, reverse flow is caused by negative pressure, or vacuum, in the supply piping. With backpressure, reverse flow happens when the downstream pressure is greater than the supply pressure. The types of backflow assemblies are broken into six categories, or methods of backflow prevention:

- Air gap assemblies use physical separation — by an air space — of drinking water and a potential source of contamination. Air gaps are applied in only those instances where the loss of system pressure is acceptable. It’s considered the best backflow system, but isn’t practical for modern plumbing systems.

- Double check valve assemblies (DCVAs) consist of two independent check valves. They protect against backsiphonage or backpressure. This type of valve is used under continuous pressure, low-risk connections. Typical uses of these devices include lawn sprinklers, non-toxic fire sprinkler systems, commercial swimming pools and similar applications. A DCVA is approved for moderate risk. A related device, the double check detector assembly features an added bypass with meter to detect underground leaks or unauthorized water usage.

- A pressure vacuum breaker (PVB) is used on connections to non-potable systems. It protects against backsiphonage, but not against backpressure. It may be used under continuous pressure, and for low- or high-risk connections. Typical applications include irrigation and laboratory equipment. A PVB is approved for severe risk if an RP is installed upstream as well.

- An atmospheric vacuum breaker (AVB) is used only on cross connections where backsiphonage is a potential hazard. It doesn’t protect against backpressure. An AVB is approved for severe risk if an RP is installed upstream as well. The AVBs air inlet valve closes when water flows in the normal, anticipated direction. But as water ceases to flow, the air inlet valve opens, eliminating the possibility of back siphonage by introducing air into the downstream piping. This type of assembly must always be installed at least six inches above all downstream piping and outlets. Unlike a PVB, the atmospheric type cannot be used under continuous pressure. Similar to the PVB, the atmospheric type protects against both non-health and health hazard cross connections.

- Specialty backflow preventers. Watts and other suppliers also make a variety of specialty backflow preventers for point-of-use applications. Watts’ NLF9 dual check with atmospheric vent for lab faucets, for instance, includes an intermediate vacuum breaker to provide protection against backsiphonage. Specialty backflow devices are approved for moderate risk only. Sizing is determined by system requirement. In most cases, backflow preventers are sized to be line-sized, but not necessarily in all cases.

- A reduced pressure zone backflow preventer (RPZ) delivers the highest level of protection against backflow and are typically applied in health-hazard cross connections. A RPZ can be used on all direct connections subject to backsiphonage or backpressure, or a combination of the two, and on systems operating under continuous pressure. For instance, Watts’ 909 offers sophisticated RPZ protection with a high discharge rate due to its dual-ported relief valve. The double-seated relief valve design allows the admission of air through one passage to accelerate the discharge of potentially contaminated water from the intermediate zone of the assembly. RPZ devices are approved for severe risk. A device of this caliber is required for conditions of extreme risk, when backpressure and backsiphonage may be combined with the fouling of both internal checks. With both checks fouled, the discharge capacity of the relief valve is left to safeguard the water supply. Typical RPZ installations include main supply lines, boiler feed lines, medical aspirators and other health hazard connections.

Discharge

All too often RP manufacturers receive returned valves as defective, when, in fact, the valves are designed to be serviced in-line. If discharge occurs upon installation, it simply needs cleaned and put back in service.

It’s not a matter of if the unit will discharge water, but when. When the valve discharges, it’s nearly always fouling on the first check. If dirt has caused damage to the check, then the elastomer needs replaced. Adequate floor drain capacity needs to be provided to accommodate discharge water from the relief valve of the RP.

Second Annual National Backflow Prevention Day: Aug. 16

Founded just last year, and will be celebrated for many years to come, the date Aug. 16 holds new significance to those whose lives are improved through backflow prevention. You might be surprised to know that, essentially, billions of people worldwide have backflow technology to thank for their good health.

Aug. 16 was officially registered in 2021 as the new, nationwide day for backflow recognition (see National Backflow Prevention Day event page) in remembrance of the 2,000 people who got sick, and the 98 who died, following a backflow incident that stemmed from the Aug. 16, 1933 World’s Fair backflow incident in Chicago.

Spearheaded by North Andover, Massachusetts-based Watts, the purpose of National Backflow Prevention Day is to acknowledge the importance of backflow prevention, to help educate the public about how this life-saving technology is used, and to recognize the water quality professionals responsible for installing and maintaining backflow preventers.

According to Danielle Swanson, backflow marketing manager for Watts, “As long as there have been plumbing systems, there have been backflow incidents. The 1933 event was one of the first documented backflow incidents.”

In 1933, Chicago city planners had abandoned quality plumbing practices — just in time for the influx of World’s Fair travelers — in favor of allowing almost uncontrolled growth. The city’s water mains and sewage system were grossly undersized, poorly designed and rich with unhealthy impurities.

Two of the hotels used to house event visitors had cross-connections with rooftop water tower fluids that contaminated domestic water, causing an influx of germs that became the link to many severe cases of amoebic dysentery. As the problem spread, and given the 12- to 30-day incubation period, there were nearly 100 deaths and over 700 documented cases spread over 206 cities in the U.S., with more than 1,000 additional cases in the city of Chicago, all traced back to the water supply of the two hotels.

Unsung heroes, “Green Berets” of the plumbing industry

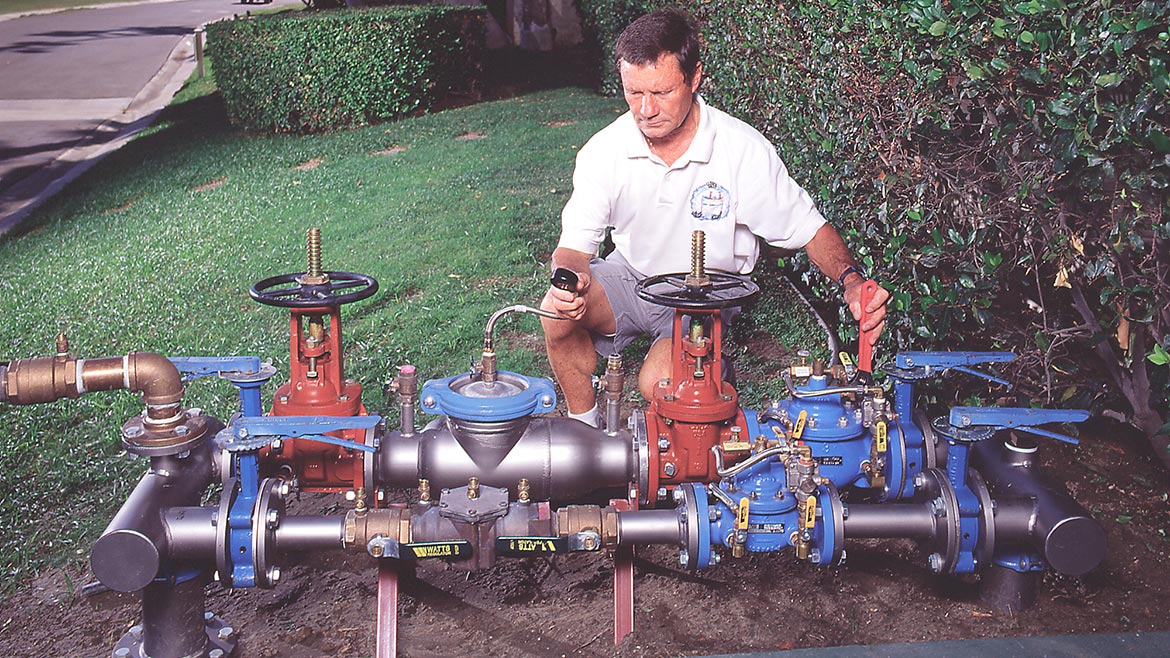

“Backflow preventers and those who test, install and maintain them are the unsung heroes of water safety,” Swanson says. “I consider them to be the ‘Green Berets’ of the plumbing industry — whose work has led them to one of the most challenging facets of the profession. I think immediately of Bernie Clark, owner of Backflow Prevention Device Tester and Clarke Sales based in Valencia, California, and Dave Yates of F. W. Behler, in York, Pennsylvania.

“Dave’s many years of backflow testing work put him in touch with us as we learned from him how he refined backflow service work,” Swanson adds. “As for Bernie, after more than 50 years in the industry throughout the SoCal region, he’s still going strong, and his company continues to grow. Both of these pros have ‘seen it all’ — from underground bunkers and confined space backflow testing and replacement to giant backflow systems and new design concepts for the landscape industry to control high pressure water breaks with specialty stations and automatic control valves.”

According to Swanson, professionals in the backflow service and testing profession often go unnoticed, and yet they play a crucial role keeping water supplies clean and safe all over the world.

“Without backflow prevention, people would routinely face the risk of consuming water with toxins, chemicals, waste and countless other contaminants,” she says. “It’s with these professionals in mind that we inaugurated National Backflow Prevention Day. We hope the industry joins us in recognizing the day, and the dedication and hard work of our nation’s backflow heroes.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!