Hydronic system provides safe and warm heating year-round at Ontario farm

Opting for a hydronic heating system instead of the radiant tube or furnace heaters that chicken farmers typically use, Haverkamp chose to install hot water boilers.

Ontario chicken farmer Hugh Haverkamp chose a hydronic heating system to heat his farm in Listowel, Ontario, Canada, because it is safe, clean and efficient. Photo credit: Aquatherm

The heating system is not only safer but also cleaner and more efficient than any Haverkamp, a lifelong poultry farmer, has ever seen or used. Photo credit: istockphoto.com/Avalon_Studio

Haverkamp chose to install the boilers in a service room adjacent to the chicken area. Photo credit: Aquatherm

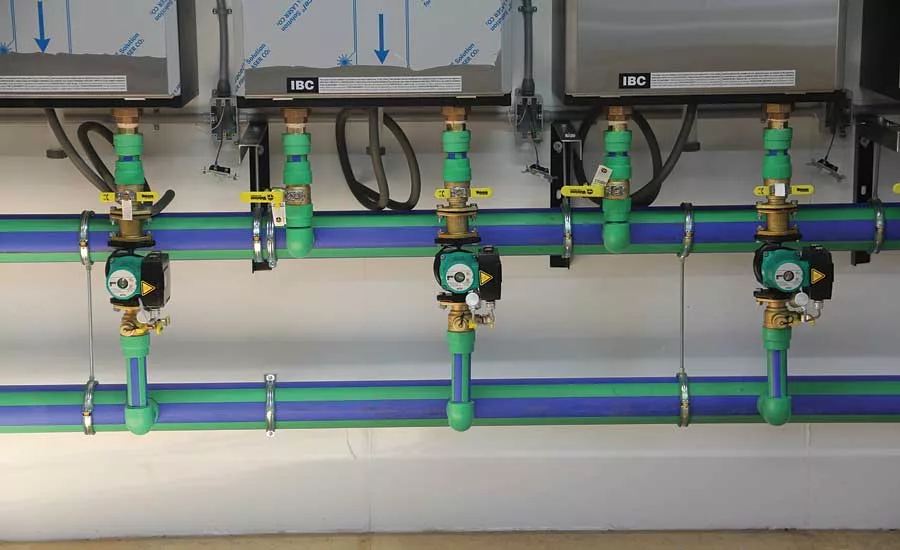

Haverkamp and Brandon Gleeson, owner/operator of Gleeson Plumbing in Moorefield, Ontario, Canada, chose Aquatherm PP-R pipe because it is lightweight and minimizes pressure drop. Photo credit: Aquatherm

Gleeson installed five IBC 399,000 Btu/h condensing boilers that stage on and off to maintain a 140° F supply water temperature inside the building. Photo credit: Aquatherm

Hugh Haverkamp has 35 days to take a barn full of baby chicks from a weight of less than 2 ounces to 5 pounds. That not only takes a lot of chicken feed, it takes a lot of heat, especially when you raise more than 500,000 chickens a year.

As a chicken farmer in Listowel, Ontario, Canada, Haverkamp knows all too well how difficult, costly, and even dangerous a challenge that can be. In recent years, Ontario livestock fires have resulted in as much as $35 million in losses per year, not including loss of equipment, agricultural products, or livestock.

Haverkamp experienced such a loss himself when one of his chicken barns went up in flames in 2016. Although the cause of the fire was never determined, he decided to rebuild with a new heating system that would not only reduce his heating cost but eliminate any combustion flame inside the broiler barn.

Opting for a hydronic heating system instead of the radiant tube or furnace heaters that chicken farmers typically use, Haverkamp chose to install hot water boilers in a service room adjacent to the chicken area. From boilers to terminal units, the entire heating system is piped with Aquatherm Blue Pipe polypropylene-random (PP-R) piping. The heating system is not only safer but also cleaner and more efficient than any Haverkamp, a lifelong poultry farmer, has ever seen or used.

Boilers for broilers

Heating systems are necessary in poultry barns for the development and weight gain of broiler chickens that are raised specifically for the food industry. Poultry farmers adjust the heat of the barns as the chickens grow, typically starting out at a space temperature of about 91° F for newly hatched chicks, then gradually decreasing the heat to about 68° over a period of five weeks.

By this time, the broilers have neared their market weight of 5 pounds, assuming the barn temperature has been maintained properly. Chickens tend not to eat if they are too hot or cold. A consistent, evenly distributed temperature stimulates their appetites and encourages activity, both of which are necessary for optimum development.

Brandon Gleeson, owner/operator of Gleeson Plumbing in Moorefield, Ontario, Canada, designed and installed the heating system for Haverkamp’s new barn. Gleeson, part of a family of chicken farmers himself, was intimately aware of the unique challenges associated with heating a broiler barn.

Honoring Haverkamp’s desire to not use combustion flames inside the chicken area, Gleeson installed five IBC 399,000 Btu/h condensing boilers that stage on and off to maintain a 140° supply water temperature.

The boilers are connected to a 4-inch Aquatherm Blue Pipe header pipe that supplies 3-inch pipes routed from the service room to the two-story chicken barn. A Wilo pump with two motors circulates 130 gpm of water into the system, which is split between the upper and lower levels at 65 gpm.

The water is routed through 1½-inch and 1¼-inch Aquatherm Blue Pipe, which supplies five Landmeco Calori-Air air-handling units per floor. These units, designed specifically for the poultry industry, hang from the ceiling and include a water-to-air heating element and a fan to distribute heat into the barn. Had Haverkamp opted for traditional tube heaters, he would have had to install 10 units per floor.

Given the total 2,000-foot length of mostly suspended pipe, the project would have been extremely difficult to install had Gleeson used black iron pipe instead of Aquatherm PP-R piping systems. It also would have been messier.

“If we were to have run black pipe, we would have had to use a larger size to maintain the same velocity. The smallest size we could have used in the distribution would have been 2 inches, whereas with Aquatherm we could do it with 1¼-inch pipe,” Gleeson said.

Aquatherm PP-R pipe has an extremely smooth interior surface, which minimizes pressure drop; therefore, a smaller diameter pipe often can be used. It is also extremely lightweight. Gleeson and just one other worker were able to install the entire system in less than a week using Ritmo hand-held socket welders to create nearly 200 connections. The crew of two did all of the cutting and pipe fusing on the floor, then lifted the pipe in 200-foot sections for installation.

Aquatherm pipe and fittings are made with Fusiolen PP-R, a material that is engineered to have an ideal melt index for socket fusion and butt welding, resulting in connections that are completely homogeneous with the rest of the pipe. The fusion process is quick and simple and yields a virtually leak-proof system. Unlike metal pipe, there is no open-flame welding, solder, or finish sanding necessary, all of which appealed to Gleeson.

“People like nice, clean joints. They don’t like to see pipe dope smeared everywhere. Aquatherm eliminates the messiness you often see with metal pipe. And the only place you must use dope [or pipe thread tape as preferred by Aquatherm] is on the threaded connections,” Gleeson said.

Recouping the cost

Poultry barns are notoriously expensive to heat, especially in cold climates like in Ontario. The high ventilation requirements along with the high space temperatures can peck away at a chicken farmer’s profits. So, even though hydronic systems have a greater installed cost than radiant tubes or furnaces, they can be a good investment for professional farmers like Haverkamp, who raises several hundred thousand chickens per year. Haverkamp ran his own cost of performance numbers and anticipates a five- to six-year payback.

“I like to make things better when I can,” Haverkamp said. “If you ask me whether I’d do it again, I’d tell you I would. It’s nice and clean, and I don’t have wires hanging all over the place. Brandon [Gleeson] did a fantastic job.”

Gleeson is just as pleased with the appearance of the piping job as he is confident of its performance.

“It looks beautiful. [Aquatherm] is a nice, solid pipe to work with. And you’re guaranteed no leaks once you pass the pressure test,” said Gleeson, referring to the fact that PP-R pipes are not vulnerable to the corrosion and pitting that lead to leaks in metal pipe systems.

Using Aquatherm, a properly executed fusion weld should last a lifetime. In fact, Aquatherm backs their products with an extensive, 10-year, multimillion-dollar warranty that covers property damage, financial loss, and personal injury.

That’s a nice insurance policy for hardworking farmers whose livelihood depends on the precious livestock within their barns.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!