Water quality makes and breaks hydronic systems

Luckily, there are products, solutions, and best practices that help improve water quality.

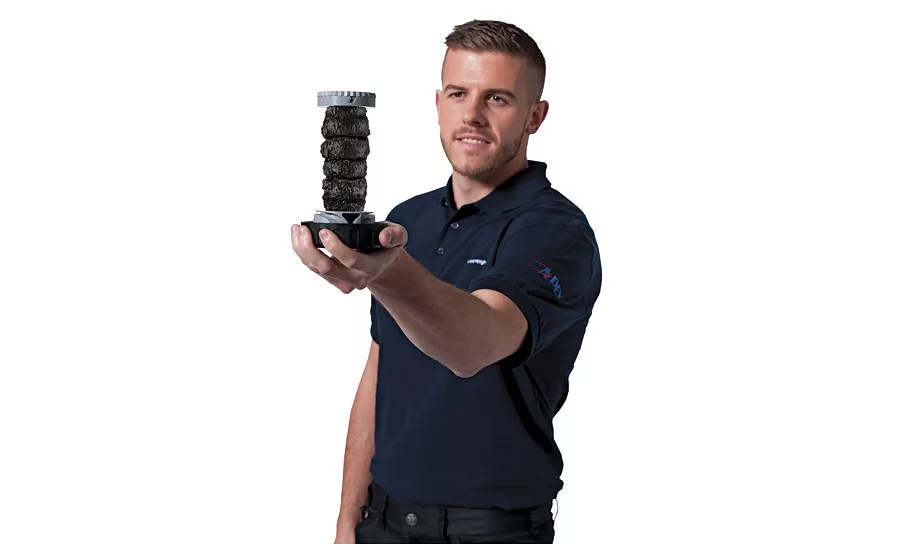

Some boiler manufacturers may offer extended warranties to end users who take precautions to ensure high water quality, which could include installing a magnetic filter like the ADEY MagnaClean pictured here. Photo credit: ADEY Innovation LLP

In boilers and water heaters, like the CB Series of Combi Boilers from Noritz pictured here, poor water quality can lead to impaired heat transfer, leaks, and system failure. Photo credit: Noritz America Corp.

Poor water quality can cause scaling, decreased efficiency, leaks, or worse, and achieving and maintaining the appropriate water quality for a given hydronic heating system helps ensure the system’s longevity and performance.

Luckily, there are products, solutions, and best practices that help improve water quality, boost system performance, and extend the life of hydronic systems.

Bad water, big problems

“Hydronic systems are large investments that can, if properly maintained, last for decades,” says John Siegenthaler, PM columnist and principal of Appropriate Designs in Holland Patent, N.Y. “Poor water quality will shorten the life of otherwise well-designed and properly installed systems. … [It] can lead to scale formation, which decreases boiler efficiency. In some cases, it can also lead to corrosion that can cause leaks in the system that can be very expensive to repair.”

In boilers and water heaters, poor water quality leads to issues with heat transfer and system deterioration, eventually resulting in leaks, says Sammy Alvarado, marketing assistant for Noritz America Corp.

“The best way to diagnose an issue before it occurs is to consult with a professional heat technician to measure the quality of the water in your hydronic system to ensure the correct amount of chemicals is being used,” Alvarado says. “The testing of the hydronic system is a great way to prevent damage to the system by ensuring it has the proper water quality.”

Heat exchangers and pumps, in particular, are often sensitive to water quality.

“High-efficiency boilers, for example, feature narrower waterways than older models, which helps increase efficiency, but if water quality is not properly maintained, these narrow waterways can be prone to blockage as magnetite combines with lime scale to form a hard enamel-like coating, which reduces pipe diameter,” says Tom Tonkins, business development director for ADEY Innovation LLP. “Likewise, ECM circulators can also suffer as a result of poor water quality, therefore reducing system efficiency.”

Hard water is a very common water quality issue that requires ongoing maintenance in order to prevent damage to equipment and components, Falsken Water Systems President and owner Dennis Falsken points out.

“Unfortunately, it’s not until a failure of a heater, pump, valve, or other water-using component occurs that there are obvious signs of more needed repairs created by the water.”

Mark Fadoul, director of business development, U.S. commercial/wholesale business, Novo Water Conditioning, also says water hardness plays a significant role in hydronic system performance and longevity.

“Hardness is the measurement of Calcium and Magnesium in the water, which, when heated, forms scale that builds up in boilers, pipes, water heaters, and other water-using appliances,” he explains. “Hardness buildup in a system affects the efficiency of appliances, resulting in higher-than-normal energy costs due to a layer of scale insulating the transfer of energy.

“A common cause for water heater failure is the cracking of the liner due to the expansion and contraction of the scale inevitably causing leaks,” continues Fadoul. “Scale buildup can also cause restricted flow or leaks within chiller or heat exchanger tubes, causing complete breakdown.”

Warranty issues

While poor water quality can wreak havoc with hydronic systems, it can also sometimes void system warranties so that if the system fails prematurely due to scale buildup or a similar problem, it is not covered under warranty by the equipment manufacturer. In fact, many boiler manufacturers now specify minimum water quality standards that are necessary to keep the boiler within warranty, Siegenthaler says.

“Manufacturer’s warranties may be affected if the end user does not ensure the water quality remains within the manufacturer’s recommended levels,” Alvarado says. “This can void the warranty, which can lead to costly efforts to fix damages caused by a leaking system.”

“Let’s take the case of tankless water heaters,” says Fadoul. “Tankless water heater manufacturers have a specific level of hardness within their warranty stating the maximum level of hardness to be acceptable or the warranty is void. Tankless heaters are sold on low-cost energy consumption, and when you put them on hard-water applications, you are defeating the purpose of an energy-efficient water heater.”

Water quality is such an important factor in the wellness of a hydronic system that some manufacturers will extend warranties for those who take preventive measures to ensure water quality.

“If total system health is maintained properly by the use of magnetic filtration and system formulas and checked annually, then the life span of a boiler is positively impacted,” Tonkins says. “Because of this, in the U.K., it’s common practice for manufacturers of hydronic heating system components to offer extended warranties when magnetic filters are installed.”

Improving water quality

As with any other mechanical equipment, preventive maintenance is vital, and with hydronic systems, that includes maintaining the water running through the equipment.

“Some of these proactive measures can be taken by a homeowner, but it’s recommended to have a licensed professional do the work,” says Alvarado. “Homeowners can conduct inspection of the air inlet filter on the heating system to ensure there is no restriction on air flow necessary for combustion. Next, ensure the dirt trap on the heating system is cleaned and there is no excess buildup of metals in the system. If you observe freezing or a noticeable loss of heating in the system, adding additive can improve your system’s performance. In most situations, flushing out the system will clean out any excessive metal deposits that can occur over time.”

Depending on the equipment’s requirements and the quality of the water, there are several products available to help maintain the water within hydronic heating systems.

“They include devices such as air separators and magnetic dirt separators, which improve the physical water quality,” says Siegenthaler. “Devices are also available to demineralize water by removing chemical ions. The use of demineralized water is especially important if antifreeze will be used in the system.

“Finally, there are chemical products which can be used to physically clean the inside of the system — remove scale, oils, fluxes, and so on — and chemical stabilizers that provide very thin coatings on internal surfaces to protect them against corrosion,” he continued. “These chemicals also help stabilize the pH of the system water.”

Being thorough is extremely important when servicing or installing equipment.

“Take the time to have the water quality determined and correct any issues using a qualified water treatment person that is familiar with hydronic applications,” says Falsken. “Water quality, if not addressed in the beginning, can cause very serious irreversible problems within a system and is generally very economical to provide.”

All it takes is a little time and a few questions, says Falsken.

“Things we ask are [if it is] closed- or open-loop; if domestic water will go through the system; what, if any, additives will be added to the water; if the water be changed out, and if so, how often; and how much water will be needed to fill the system.”

“Improved water quality — in fact, total system health — should be the goal of any hydronic heating contractor,” Tonkins says. “ADEY has introduced a Best Practice System Process. This five-step routine, along with the required formulas and equipment for implementing the process, is designed to address water quality by cleaning and protecting hydronic systems to ensure maximum efficiency, reduced emissions, and cost savings.”

The best thing to know as a contractor is that not all jobs are created equal, says Alvarado.

“Looking to the manufacturers’ manuals and recommendations is always a good practice when getting the job done right,” he says. “Not every hydronic system is set up the same way and will vary from job site.”

Water quality has not always been top-of-mind for equipment owners and operators, but that is “changing quickly as new products for achieving high water quality become available, and as manufacturers of boilers and other heating and cooling equipment are increasingly specifying minimum water quality standards to keep their equipment in warranty,” Siegenthaler says.

The most important takeaway is that achieving and maintaining proper water quality in a hydronic system, either closed- or open-loop, is extremely important. And, it is an ongoing process.

“Water quality is not a one-time fix,” says Tonkins. “It has to be maintained, and it requires follow-up and proper care in order to achieve favorable results. Not enough can be said for the importance of water quality in maintaining a system. In ADEY’s opinion, it is the corner stone of hydronic heating.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!