Viega expands U.S. manufacturing footprint

Viega reached a milestone during the summer with the production of its first U.S.-made metal pipe fittings in its newly expanded manufacturing facilities in McPherson, Kan.

An aerial view of Viega’s manufacturing and distribution center in McPherson, Kan. Photo credit: Viega

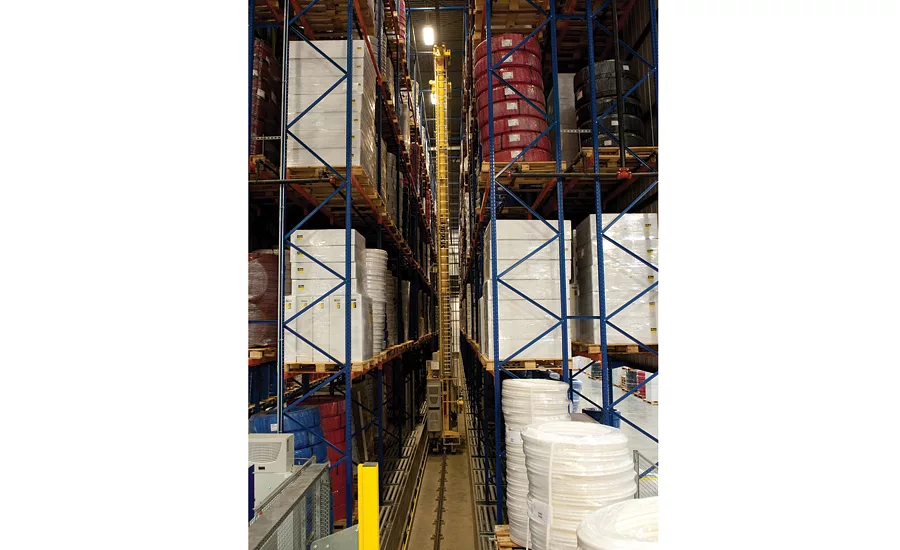

Viega has centralized production of its PEX tubing in McPherson. Photo credit: Viega

Viega reached a milestone during the summer with the production of its first U.S.-made metal pipe fittings in its newly expanded manufacturing facilities in McPherson, Kan. Almost simultaneously, the company consolidated operations of its PEX manufacturing operation by shifting its resin production to McPherson. Viega has been selling metal fittings produced in Germany where the company is based. It previously was manufacturing PEX resin at its facility in Peachtree City, Ga.

Both manufacturing moves were planned long before Viega announced in April that it will move its North American headquarters from Wichita, Kan., to the Denver area by the end of next year. The company is building new corporate offices in Broomfield, Colo., in a structure whose architect took inspiration from the shape of a Viega pipe fitting. The same property will house a new educational facility that will complement Viega’s training center in Nashua, N.H., which opened in 2006 and has trained 25,000 industry professionals since then.

Nevertheless, both recent manufacturing moves emphasize that Kansas remains a significant part of the growth plans for the company through the production and distribution center in McPherson. Viega hosted an open house Aug. 24 when company executives and managers met with members of the trade media, including Plumbing & Mechanical. The event included tours of the new and expanded facilities and a discussion of industry trends.

Manufacturing capabilities

Viega broke ground in November 2014 for the 80,000-sq.-ft. manufacturing addition in McPherson. The new Viega metals manufacturing facility cold forms 1/2-in. to 2-in. press-by-press and straight elbow carbon-steel MegaPress fittings for water applications and MegaPressG fittings for gas applications.

“By manufacturing it here, we can more effectively and efficiently deliver MegaPress product solutions to our distributors and customers across the country,” President and CEO Dave Garlow said. “These fittings are the first Viega metals products to be made right here in the United States.”

When at full capacity, the new facility can manufacture 3 million MegaPress fittings per year. In addition, Viega assembles 250 different MegaPress fitting configurations in its metals production facility and can assemble 1.5 million fittings annually.

Eric Wicker, Viega’s McPherson-based director of manufacturing, noted: “We built the metals manufacturing facility with plans to add more MegaPress production cells and additional high-tech manufacturing processes.”

Wicker also oversees the production of the company’s ViegaPEX Ultra tubing for plumbing systems. The tubing produced in McPherson includes the standard blue, red, white and black ViegaPEX tubing as well as the purple ViegaPEX tubing for reclaimed water, which was introduced in February.

“We’re now able to monitor the materials more closely and make innovations much faster,” said David Perciful, Viega’s McPherson-based director of quality assurance. “We work with thousands of pounds of materials each day for PEX tubing production here in McPherson with a close eye on quality.”

The PEX resin processes previously done in Georgia were consolidated into an existing 10,000-sq.-ft. space in McPherson. The move eliminates the need for additional packaging and shipping, which reduces the overall environmental impact and carbon footprint of its PEX production.

Industry trends

Product manager Seth Larson, who oversees the PureFlow line, identified a number of construction industry trends that influence Viega’s business. They include:

-

Revitalization of downtown areas, with an emphasis on mixed-use buildings;

-

Rising demand for and construction of multifamily housing;

-

Growing acceptance of plastic piping systems in commercial applications;

-

Aging municipal water and wastewater infrastructure;

-

Water reclamation systems becoming more popular; and

-

An aging and shrinking skilled labor force.

-

Product manager David Desjardins cited heating-and-cooling trends in residential and commercial buildings:

-

Remodeling projects are gaining strength in the residential market;

-

New homes where radiant technology is utilized in only part of the house are becoming more popular;

-

Customers need to integrate their heating and cooling with other home systems;

-

On the commercial side, engineers are investigating the use of radiant cooling in projects;

-

About half of net zero buildings use radiant technology; and

-

Both engineers and contractors need assistance with design and installation of radiant projects.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!