A Little Floor Warming Please John Siegenthaler

When it comes to comfort, even a small heated floor makes a big impression.

|

| FIGURE 1 |

A question that often comes up when discussing hydronic heating options is how to tie a small area of floor heating in with a baseboard system. There are a number of approaches depending on the type of floor heating being considered as well as how the system will be zoned.

Most fin-tube baseboard systems are designed to operate at relatively high water temperatures (typically in the range of 180 to 200 degrees F), and do not use outdoor reset control. If the floor heating method being considered requires lower supply water temperature, a mixing valve must be installed between the high and low temperature portions of the system.

A three-way thermostatic mixing valve is arguably the simplest approach. A basic radiant subsystem using such a valve is shown in Figure 1. Note the closely spaced tees used to couple the radiant subsystem to the source of hot water. This detail eliminates interference between the circulator in the radiant subsystem and any other circulator(s) in the system.

What you connect the radiant subsystem to depends on how you want it to operate. Will it operate as an independent heating zone, or be "slaved" to the operation of a baseboard zone circuit? Each approach has its pros and cons.

For example, if the radiant subsystem is tapped into an existing baseboard circuit, it will lower the water temperature to baseboards downstream of the tap in location. If those baseboards were marginally sized there could be a cold room callback in the making. On a new installation, you can account for the temperature drop caused by the radiant subsystem and increase the length of the downstream baseboards when necessary.

Using a baseboard circuit to supply the radiant subsystem on a system without boiler reset control also means those floor areas will only be heated when the baseboard loop is circulating. This may be fine on some jobs, but watch out for situations where the thermostat controlling the zone can be satisfied by the fast-responding low mass baseboard long before the higher thermal mass floor has warmed up. In such cases it's better to pipe the radiant subsystem as an independent zone.

|

| FIGURE 2 |

On Demand

Figure 2 shows three methods of supplying hot water to small, independently controlled radiant heating subsystem. The first approach uses a zone circulator to supply a hot water bypass loop. The second uses a zone valve to control flow through the bypass circuit. The third uses a "wild" hot water bypass loop.

If a "wild" hot water bypass is used, there will be flow through it whenever the system circulator is running. The system wiring must be configured to turn on the system circulator whenever the thermostat controlling the radiant subsystem calls for heat.

A flow restricting (globe) valve should be installed in the bypass loop when that loop is controlled by a zone valve or runs wild. Partially closing this valve prevents a large percentage of the circulator's flow from racing through what may be a relatively low resistance flow path, thus robbing the other zones of their share of hot water. Set the flow restrictor valve for a temperature drop of about 40 degrees F between the supply and return side of the bypass loop.

Make this adjustment when the boiler and radiant subsystem are operating at or close to normal design load temperatures. With a boiler supply temperature of at least 180 degrees F, the return temperature to the boiler should be high enough to avoid sustained flue gas condensation.

If a zone circulator is used in the bypass loop a flow restrictor valve is not necessary. The higher the flow rate in the bypass loop, the higher the return temperature to the boiler.

|

| FIGURE 3 |

For Outdoor Resets

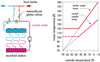

If the baseboard system uses outdoor reset control, there's another possible way to set up the radiant subsystem. Install a pair of globe valves or a single manually adjusted three-way valve as the mixing device and let the radiant system take advantage of reset control.

It's another application for the concept of proportional reset that we've discussed in the past. When a higher temperature loop supplies water for mixing into a lower temperature subsystem that uses fixed mixing proportions (e.g., manually set mixing valves), and the higher temperature loop is reset, then the mixed subsystem will also be reset, only along a shallower reset line as shown in Figure 3.

If the boiler reset control is properly adjusted, the baseboard zones should operate almost continuously during the heating season. That's because the water supplied to the baseboard circuits is just warm enough to provide the necessary heat output for the prevailing condition. Flow only stops in the case of internal heat gains or during very mild weather when the boiler reset operates on a minimum supply temperature setting to prevent flue gas condensation. This quasi-continuous circulation will help even out the heat delivery of the radiant subsystem.

Still another possibility is to use a "high temperature" radiant subsystem such as tubing suspended in the air space between the floor joists. The idea is to operate the floor heating subsystem at the same water temperature as the baseboard zones. The radiant circuit(s) can generally be piped just like a baseboard zone, without need of a mixing device or additional circulator.

A small area of floor heating could also be set up as a "shunt" circuit as shown in Figure 4. The flow restrictor valve between the tees is partially closed to provide a pressure differential that pushes flow through the floor circuit. If the radiant circuit creates a high head loss, it could even be set up as a secondary circuit with its own circulator. The latter situation is unlikely except when the circuit is abnormally long and/or uses very small tubing.

Still another variation is to route hot water through a baseboard or perhaps a panel radiator, and continue that circuit through a suspended tubing below the floor. What could be better than a toasty towel and a warm floor after a shower on a cold January morning?

A word of caution: Don't pump 180 degree F plus water through a floor heating systems designed to operate at lower water temperature. There's no point in cooking your customer's floors and your reputation at the same time.

|

| FIGURE 4 |

Protecting The Boiler

I've stressed the need to protect boilers from sustained flue gas condensation on numerous occasions, especially when a low temperature/high mass distribution system is involved. However, is boiler protection necessary when a small area of low temperature radiant floor heating is tied to a system with predominantly high temperature loads?

The answer depends on the size of the low temperature load relative to the high temperature load. What must be avoided is a situation where the distribution system can pull heat away from the water faster than the boiler can supply it. A cool floor slab can strip Btu away from the water passing through it three to four times faster than under normal design load conditions.

With this in mind, I suggest that if the low temperature/high mass radiant load represents 20 percent or less of the total load on the boiler, and if there's bypass piping to blend some hot water with the cooler return water, then no additional boiler protection schemes are necessary.

Boiler protection hardware is also unnecessary when a high temperature/low mass radiant subsystem (such as tubing suspended in floor joist cavities) is used. The temperature of such a radiant subsystem will rise quickly following a cold start allowing the boiler to rapidly evaporate any initial condensate.

The next time you're perusing a prospective baseboard heating job look for those tile floors in bathrooms, kitchens and mudrooms, or that future hobby room in the basement. Make sure your prospective client knows you can mix in some areas of radiant floor heating, where it makes sense, even though most of the system uses baseboard. Providing that combination might even be the specialty that sets you apart you from less imaginative or technically informed competition.

After all, when it comes to comfort even a small heated floor can make a big impression.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!