Tech advances spur digital job site growth

Firms of all sizes are using new technology to optimize bids and service times while minimizing callbacks.

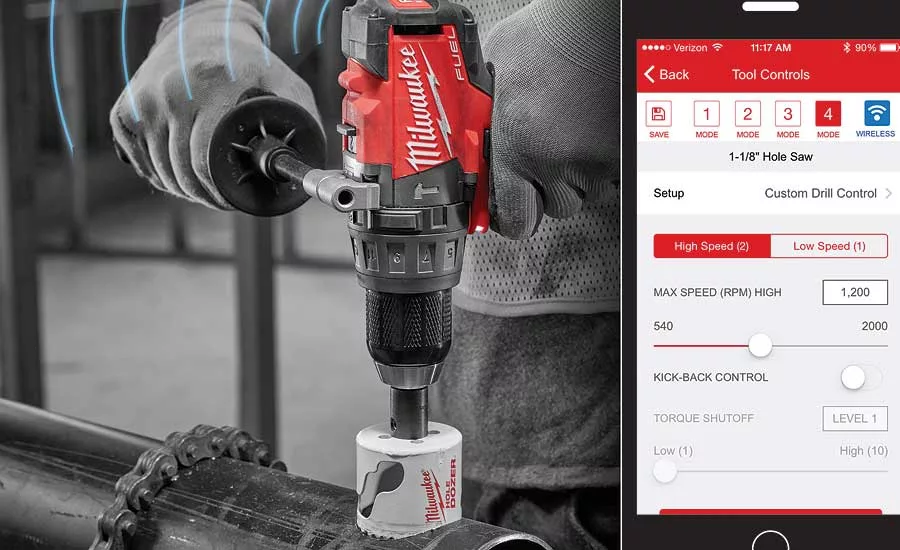

Built on the principles of “Customize, Track, and Manage,” Milwaukee Tool’s One-Key combines tool and software technology to develop a tool management solution that provides a better way for work to get done. Photo credit: Milwaukee Tool

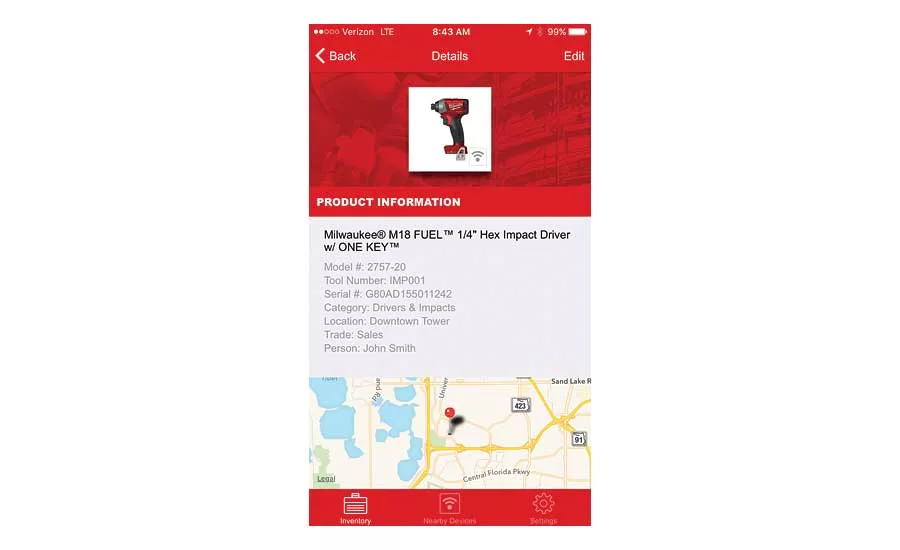

Tracking tools in real time has become as easy as opening up a mobile app and looking at a map. Photo credit: Milwaukee Tool

The Internet of Things is no longer “the next big thing” — in this day and age, it is a common part of the world that makes almost everything from homes, phones, and cars “smart.” Consumers now have virtual, interactive, and instantaneous experiences daily, and it is shaping their buying behaviors and decisions.

Indeed, today’s market is rapidly changing. Now more than ever, plumbing and mechanical professionals in both the commercial and residential spaces are feeling the impact that IoT and other technologies have had on their businesses, and this has fueled a need for improved consistency and efficiency in order to compete for the job.

It comes as no surprise that the need to meet these demands has given rise to the digital jobsite. Firms of all sizes are using new technology to optimize bids and service times while minimizing callbacks. Luckily, solutions are emerging for all steps of the process.

The rise of BIM

One of the largest catalysts of the rise of the digital jobsite commercially has been the emergence of Building Information Modeling. This 3-D model-based process equips all members of the building process — architects, engineers, project managers, and the tradesmen — with effective tools that help them efficiently plan, design, construct, and manage the overall project from concept to occupancy.

Before BIM, a large amount of time went into the tedious back-and-forth between the design team, construction team, trades, building owner, and more. Now, through the use of BIM, the metaphorical walls are torn down between those involved in the process. A digital representation of the building is created and networked to support decision-making of key individuals involved, ensuring all impacts of every decision are seen and accounted for.

BIM programs have been instrumental in reducing budgets by allowing those involved to provide more accurate estimates and eliminate change orders. They’ve also been of great assistance in overall improvement of project schedules by enabling cost-effective prefabrication and reducing overcrowding or stacking of trades on-site.

These types of programs have also been an ideal solution for large commercial plumbing and mechanical contracting companies by allowing them to expand their competitive reach beyond traditional regional constraints and bid on projects all across the country.

Residential solutions

Whereas BIM has been the hero of the commercial digital jobsite, residential professionals have a different set of needs. Knowing how to win the job, streamline operations, and efficiently get multiple jobs done per day is key.

Residential service programs like ServiceTitan provide these professionals with a cloud-based field-management platform that offers a vast array of features that track everything from sales to scheduling and marketing. ServiceTitan and other similar programs allow residential plumbers to use their smartphones to easily map out routes for the day, handle bill pay, schedule appointments, and respond to customer feedback promptly. This is also a major step in documentation and record-keeping.

Even just a decade ago, getting directions to a customer’s home or business could be tough. Nowadays, residential plumbers can get in easily, take notes for the customer, efficiently get the job done, and automate receipts from a single device through cost-effective project and client management tools. With less time needed to worry about and manage the business, these professionals can now focus more on their skilled labor and expertise.

These companies can also create grassroots marketing approaches through the creation of online presences on a number of social media sites that have proven to be popular places for customers to research service providers, such as Facebook and Instagram. In addition, the emergence of popular trade forums has brought forth a growth of collaboration between plumbing companies sharing helpful tips and showing examples of successful jobs.

Tools and equipment

The digital jobsite has given way to an abundance of solutions that help companies plan, budget, and approach their projects more efficiently. Surprisingly, despite the availability of all these solutions to plan materials and labor, when it comes to managing tools and equipment, there are few good inventory-management solutions available today.

In years past, companies have had to resort to hugely expensive programs, tedious spreadsheets, or cumbersome folders. These inefficient inventory-management systems could result in missing or undocumented equipment. When tradesmen spend more time looking for tools and less time working on the project at hand, it has a significant impact on labor costs — and, in turn, the bottom line.

First introduced little more than a year ago, Milwaukee Tool’s One-Key system is the first digital platform for tools and equipment. Built on the principles of “Customize, Track, and Manage,” One-Key combines tool and software technology to develop a tool management solution that provides a better way for work to get done in a company of any size.

The application offers a variety of functionalities to increase company and user productivity ― including the ability to manage inventory, track tools in real time, and even customize compatible products. One-Key’s Tick solution can even provide a way for companies to track any tool or piece of essential equipment, no matter the manufacturer.

“I am responsible for managing all small tools and equipment for our company, and before One-Key, if someone took a tool without proper documentation to a job site, we were at a loss as to where it was,” says Jack Vanderford of JH Kelly in Longview, Wash. “With tracking capability inside One-Key power tools, and now with the Tick tracker, we have been able to manage inventory and recover tools and equipment easily.”

Missing and stolen tools

Every contractor knows what it’s like to have their truck taken, or they know someone who has had it happen. Depending on the situation, this can significantly impact a professional’s livelihood. Numerous companies are working toward solutions that deter tool theft. For example, One-Key provides theft protection by giving companies the power to lock-out tools to render them useless if stolen.

“I recovered almost $3,000 worth of tools with the assistance of One-Key tracking in my drill driver and impact driver,” says Dave Spurlock of Tactical Innovation in Colorado. “One day I was getting gas between jobs and put my keys down on the floor of the truck to take a phone call. Unfortunately, someone was watching and stole my truck and all the tools in it when I turned my back for less than three seconds. With the help of One-Key tracking, we were able to show police on a map where the tools were and recover them. The thief didn’t see it coming.”

What’s next?

That question can really only be answered by today’s plumbing and mechanical contracting companies. There are solutions across the board, from project planning to construction, which have tremendous ability to improve efficiency and consistency for professionals so that they have the ability to compete in the days to come. It will be no surprise that companies that remain hesitant to integrate technology into their processes will find it difficult to stay competitive. Meanwhile, those who can stay ahead will thrive.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!