Zoned hydronic distribution system

December 2014 The Glitch and The Fix

December 2014 Glitch drawing: An installer sets up a zoned distribution system as shown above. To keep it simple, he uses the same size piping for the headers and all the distribution circuits. The heat source is a low-mass copper tube boiler with high flow resistance.

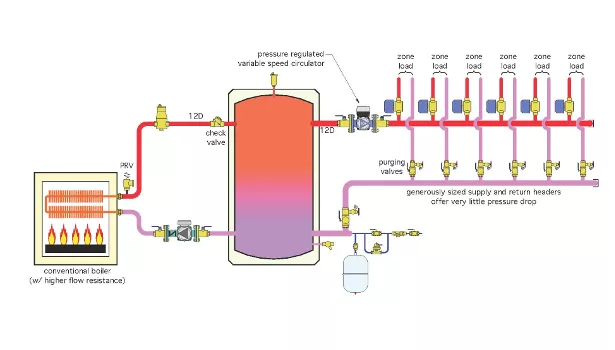

December 2014 Fix drawing: Any “flow sensitive” boiler supplying a system using zone valves should be decoupled from the distribution system through some means of hydraulic separation. In the Fix drawing above, this is accomplished with a buffer tank, which also adds thermal mass to prevent boiler short-cycling.

The Glitch

An installer sets up a zoned distribution system as shown above. To keep it simple, he uses the same size piping for the headers and all the distribution circuits. The heat source is a low-mass copper tube boiler with high flow resistance.

The distribution system operates at water temperatures high enough that sustained flue gas condensation will not occur. To prevent heat migration, he installs a spring-loaded check valve at the beginning of each zone circuit, just above the header. To control differential pressure, he installs a partially open globe valve across the ends of the headers. He sets the globe valve for one turn open.

Can you identify and describe at least six details that should be changed?

The Fix

Here’s what’s wrong and how to correct it:

1. The high flow-resistance boiler will create significant variation in zone flow rates depending on which zones are open. The boiler’s low thermal mass can create noises from the boiler’s heat exchanger under low flow conditions when only one or two zones are operating.

2. The partially closed ball valve is a poor excuse for proper differential pressure control across the headers. A variable-speed, pressure-regulated circulator is now the state-of-the-art method for providing such control in systems using valve-based zoning.

3. Headers should always be generously sized to minimize pressure drop along the length of the header. This plays a big part in providing hydraulic separation between the load circuits.

4. Any “flow sensitive” boiler supplying a system using zone valves should be decoupled from the distribution system through some means of hydraulic separation. In the Fix drawing above, this is accomplished with a buffer tank, which also adds thermal mass to prevent boiler short-cycling.

5. It’s never a good idea to install check valves near fittings that creates high turbulence. This is the case with the check valves shown in the Glitch drawing. There should always be at least 12 diameters of straight piping upstream of any check valve to calm turbulence that otherwise will cause the check valve to rattle. However, heat migration in the Fix drawing is eliminated by simply installing the zone valves on the supply side of the zone circuits. Do this and there’s no need for check valves on each zone circuit.

6. Purging valves on each zone circuit are missing in the Glitch drawing. They are shown in the Fix.

7. The circulator location in the Glitch drawing, in combination with the likely pressure losses of the piping system, puts the circulator in a “pumping toward” rather than a “pumping away” situation with respect to the expansion tank. Installing the expansion tank near the lower inlet of the buffer tank keeps the point of no pressure change close to the inlet of both circulators.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!