Emergency ID - Your Shocking Wake-Up Card

Paul Ridilla

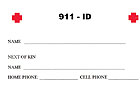

When you ask your employee who you should notify when the ambulance takes him or her off your jobsite, you will probably get his or her attention. You will need the name and phone numbers of each employee’s next of kin to fill out this wallet-size 911 ID card (click on image at right).

Would that make you think more seriously about safety precautions?

I have personally been trying to enforce safety on our jobsites for half a century. Some of these employees were relatives or close friends, but most were jobsite acquaintances or total strangers. The important factor was they were all diligent, hardworking human beings trying to earn a living in our often times dangerous construction industry. I could not stand the thought of any one of them being injured or killed and the terrible consequences for their families.

What I could never understand was the apathy of our employees who knew that accidents could happen, but surely not to them. I always related that to all of the Americans who do not wear their seat belts on our dangerous highways.

Throughout the years, I have witnessed the results of thousands of minor first-aid injuries, hundreds of rush-to-the-hospital accidents and eight fatalities. Two of those ambulance trips to the hospital actually saved my life. No one has to convince me that an accident could happen to me!

Mandating Employee Safety

My first concern for employee safety was as a jobsite supervisor. This was long before OSHA came into the construction industry in 1970, with specific rules, jobsite inspectors, citations and financial penalties.

We furnished personal protection equipment to every employee, did after-hour safety training, and held weekly on-site safety meetings. Some called these “tool box talks” or “tailgate meetings.” All of the employees attended, but very few actually showed any real interest, since much of the information did not specifically relate to what they were doing that particular week.

The apathy still existed because they acknowledged that accidents could happen, but were confident that none would ever involve them or affect their families.

In 2001 we initiated a Safe Plan of Action form (example on page 100), which every foreman from each of the different trades must discuss with each employee in his crew. They simply ask, “Do you know of any unsafe condition that could injure you on this site?” If the employee mentions a possible hazard, the foreman documents the problem and also what action was taken to eliminate it. Each employee must then sign this Safe Plan of Action, which is maintained in the jobsite trailer.

In addition to gaining upward feedback from each employee, you also have documentation of your efforts to prevent accidents. Your employees are now looking for site-specific dangers. I highly recommend initiating this Safe Plan of Action on all of your jobsites.

On the down side, you will have those employees who are still willing to play these stupid Russian Roulette games that endanger their lives as well as your business:

1. They do not wear the hard hat you furnished. They are working below other craftsmen who could easily drop a tool, a bolt, a fitting or piece of pipe that would bounce off their hard hat but would easily go right through their skulls!

2. They are using a cutting torch to cut off a piece of pipe or angle iron that is blowing hot, molten metal into their faces with high-pressure oxygen. They could protect their eyes with the goggles you furnished, but they know they don’t need them.

3. Likewise with a carborundum metal-cutting saw and a grinder or chipping hammer. After all, our eyes are easy to replace, right?

4. They are using a damaged electrical cord that has bare copper wire exposed, but they know that a little shock will not hurt them. Naturally that cord is not plugged into a receptacle with a ground fault protector.

5. You have two employees laying 6-foot pipe in a trench that is 8 feet deep. They have no hard hats and there is no shoring. The banks are not sloped properly, there are no escape ladders and the spoil was not kept back 2 feet from the edge. It’s quite evident that your competent soils person did not check and approve their safety before they entered that death trap.

If you do not visit your jobsites, you may think that these are exaggerations or just my recollection of old war stories. All of you with on-the-job experience or access to jobsites know that these examples all happened last week.

Let me share the responses that I received when I asked for next of kin information for these employees’ 911 ID cards:

- Every one of the employees without hard hats immediately put them on. One man asked me not to call his wife. He said she would do worse than dropping something on his head.

- The fellow without goggles using a cutting torch bent over and asked me to give him a swift kick in the butt. He said he couldn’t think of anything worse than being blind, but he was in a hurry.

- One of the employees using a damaged electrical cord told me he was shocked dozens of times, but it never really hurt him. I insisted on next of kin information to fill out his 911 ID and told him the next shock might be his last one.

- The two employees laying pipe in the 8-foot trench were sons of the operator sitting on the backhoe. He gave me his wife’s name and phone number for the 911 ID card. The three stopped working and the operator apologized to both of his sons and put one on the backhoe to dig the proper slope on the banks of the trench. He and the younger son then went to their truck for hard hats and ladders. He asked them not to tell their mother and went into the trench with the younger son to finish laying pipe safely.

Links

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!