PM Installation Survey: CSST

Early this year, PM sent out a survey to 1,500 Plumbing & Mechanical subscribers who are owners of plumbing, hydronic heating or mechanical contracting firms to evaluate the installation of corrugated stainless-steel tubing, and to gain a more accurate up-to-date view of the market. We received a 16 percent response rate by these companies, who are also active in new construction and industry modernizations and alterations.

CSST, introduced to the U.S. market in 1988, has recently enjoyed widespread code and contractor acceptance. The flexible, rugged tubing and fittings have seen their market increase significantly, and our survey validates these trends.

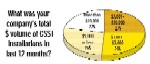

Nearly 75 percent of respondents install CSST, with an average company total dollar volume of these installations at a median price of $3,000. As for future market trends, about 60 percent believe their CSST installations will increase in 2006 as compared to 2005. Looking even further ahead, 77 percent of survey respondents expect the amount of CSST they install to increase over the next five years (20 percent believe their installations will stay the same).

PM spoke with Dan Roberts, a regional sales manager for the Gastite Division of Titeflex Corp., to uncover this upswing in flexible gas-piping usage. Titeflex manufactures the Gastite brand of CSST and fittings.

“Code acceptance has played a big part in the increase in sales and installation of CSST,” Roberts says. With all national model codes approving the product - and out in publication - jurisdictions now can accept CSST as a building tool.

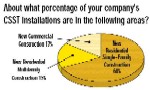

Also, with 68 percent of respondents' projects including new residential single-family construction, the soaring building markets are another factor for the increase in CSST use (17 percent of projects were new commercial construction, 15 percent new multifamily residential construction).

“Many new users of CSST are referred to the product by tried-and-true users of the tubing,” says Roberts. In tight labor markets, companies adopt the use of CSST in order to stay competitive during the bidding process.

In the past, new residential construction has been CSST's bread and butter, but the commercial end has also seen a rise in CSST usage. Places like schools, strip malls and other nonresidential projects can benefit from the ease of installation of CSST, Roberts says. In recent years, manufacturers have expanded flexible gas piping diameters to 2 inches, allowing design capabilities to increase as well.

The emergence of “hybrid” systems has contributed, too. “Black iron pipe has been installed for eons,” says Roberts. “But it still proves to be difficult in certain installations.” As land becomes more expensive and builders tend to build up rather than out, CSST can come in handy. He points out that subtle changes in the building process have made it hard to prefab difficult runs of gas piping, such as a fireplace in a vaulted ceiling or a kitchen island with gas range. If builders design their systems as hybrids - marrying traditional black pipe with CSST - these applications can be installed more smoothly and easily.

Still, because of some remaining misconceptions about CSST, there are some contractors not taking advantage of the product. Gastite's regional management is positioned nationwide to allow them to get in front of the contractor - to meet with them at local “lunch 'n learns” to raise both public and trade awareness.

But Roberts admits, “Contractors learn best from their peers.” In fact, he will arrange for interested contractors to see and hear from tried-and-true CSST customers. They're usually convinced pretty quickly, “once they get past their preconceptions,” he says.

Some other things Roberts says to keep in mind about CSST:

- Know that it's an approved product with a 15-year proven track record.

- CSST is not just for elevated pressure.

- Start small with a hybrid system. Then, once you experience the ease of installation and labor savings, incorporate runs for whole-house applications.

A complete copy of PM's “Installation: CSST Study” - including more information on product and brand decisions - can be purchased for $95. For ordering information, contact Cory Maxwell at 248/244-6415 or maxwellc@bnpmedia.com.

Links

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!