Dueling Circulators

John Siegenthaler, PE

Many of these classic header systems share common characteristics including:

- They use a heat source with very little flow resistance. A good example being a cast-iron sectional boiler.

- The “common piping” between the return header and supply header is relatively short and has very low flow resistance.

- The zone circulators are either identical or closely matched in pumping ability.

Unfortunately, many newly minted hydronic systems don't share this attribute. Instead, they use boilers with much higher flow resistance and less thermal mass relative to a cast-iron sectional boiler. The distribution systems these boilers serve often have six or more zones, some of which may be driven by high head circulators.

Big surprises await those who “cut and paste” such hardware into a traditional header-type piping layout. The resulting flow restrictions will cause some boilers to repeatedly “trip out” their internal safety switches due to unexpected temperatures or pressures. Water can flash to steam inside the boiler, causing noises that send most people diving for cover. Low flows in portions of the distribution system leave occupants shivering on the outside and steaming on the inside, especially when they remember the premium prices they paid for a modern high-efficiency comfort system.

Upon arriving for the inevitable callback, some installers try to fix these “glitches” by turning dials, typically in the upward direction. Rather than searching out the underlying cause of the problem, they try to overpower it with higher water temperatures. Most are bound to repeat the same elusive mistakes on future systems.

20/20 Hindsight

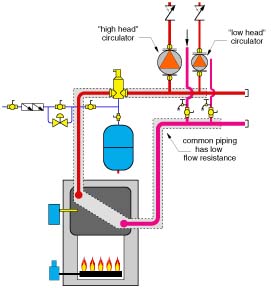

Consider the piping schematic shown in Figure 2. One of the pumped zones has a high head circulator, the other a standard 1/25 horsepower zone circulator. These pumps will tolerate each other's existence if the common piping between them has low flow resistance.However, look at what can happen when the common piping has a high flow resistance. The situation is shown in Figure 3 using pump curves and the system curve for the common piping (which includes the boiler). The high flow resistance of the common piping in combination with the steep pump curve of the larger circulator creates a major pressure drop between the headers. For the case shown, the pressure drop is greater than the “stagnation” head of the smaller circulator. Thus, if the larger circulator is running at the same time as the smaller circulator, there will be no flow through the latter. The check valve in the circuit with the smaller circulator will be back-seated by the pressure differential established across the high flow resistance common piping.

It finally dawned on me that the problem wasn't the small circulator, but the large pressure drop setup across the tankless coil when the larger circulator was operating.

Fortunately, this was easy to correct by making the indirect tank a priority load. A simple relay was used to prevent the larger circulator from operating whenever the indirect thermostat called for heat.

This solution won't always be available or desirable, especially when several loads need to operate at the same time. A better solution is to pipe the high flow resistance heat source into the system as a secondary circuit, as shown in Figure 4.

Header size / Header flow rate

1-inch type M copper / 5.5-8.2 gpm

1.25-inch type M copper / 8.2-12.4 gpm

1.5-inch type M copper / 11.4-17.2 gpm

2-inch type M copper / 19.8-29.7 gpm

2.5-inch type M copper / 30.5-45.8 gpm

3-inch type M copper / 43.6-65.4 gpm

The supply temperature sensor for the boiler reset control should be downstream of the closely spaced tees, as shown in Figure 4. This allows it to sense the true supply temperature to the distribution system rather than the boiler outlet temperature. The temperature at this location accounts for mixing at the closely spaced tees when the distribution system flow rate is greater than the boiler flow rate.

Unnecessarily Concerned

The system shown in Figure 4 often operates with considerably more flow in the distribution system than through the boiler. This just doesn't feel right to those who've spent years installing classic header systems where all flow from the distribution system passes through the boiler. Fortunately, the first law of thermodynamics doesn't see this as a problem.To understand why, you need to think in terms of Btus rather than gpm. The boiler produces heat at its rated output and puts that heat into the water passing through it. Doubling the flow rate through the boiler reduces the temperature rise across it, but has relatively little effect on the heat transfer rate.

The temperature of the distribution system will automatically rise or fall such that the rate of heat release by the heat emitters balances the rate of heat input from the heat source. That's the famous first law of thermodynamics at work. The fact that some of the distribution flow bypasses the closely spaced tees coupling the boiler to the distribution system doesn't change the fact that nature wants balanced energy flows.

If this distribution system happens to be running cooler than you expected, remember that it's only going to get hot enough to output the heat being delivered to it. If it can dissipate all the heat input at a supply temperature of say 110 degrees F, why would it want to increase to 115 degrees F, even if the aquastat on the boiler is set much higher - say to180 degrees F? The system doesn't care what you've set the aquastat to, it only cares about maintaining the balance between heat input and heat release.

The classic header approach still has a place in modern hydronics. However, when you're working with a low-mass boiler, play it safe with a primary/secondary interface between that boiler and the distribution system. Do the same for any component with high flow resistance that's located in the common piping of the header system. By doing so, you'll avoid bottlenecks in flow and let Mother Nature balance the energy flows to perfection.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!