The Glitch

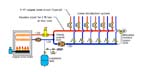

Overview:A copper tube boiler is installed as shown with six zone circuits controlled by zone valves. The installer got a great price on a “contractor pack” of 3/4-inch copper tees, so the supply and return manifolds are built with 3/4-inch copper, as are all the zone circuits. The circulator is installed on the return side of the boiler.Exercise:There are at least four errors in this design. Can you spot them?

The Fix

Copper tube boilers are “flow sensitive.” They should not be operated with low flow rates, such as might occur when only one zone circuit is operating. The correction is to install the boiler as a secondary circuit with its own circulator that maintains constant flow through the boiler regardless of flow in the distribution system.Other corrections include:

1. Moving the zone valves to the supply side of the zone circuits to prevent heat migration.

2. Ensuring there is at lest twelve pipe diameters (12D) of straight pipe on the inlet of all circulators to reduce turbulence.

3. Installing a differential pressure valve to limit differential pressure gain across the headers under partial load conditions.

4. Sizing the headers for a flow velocity of 2 feet/second when all zone circuits are on. This keeps the pressure drop along the header very low and helps prevent changes in zone flow rates as other zones turn on and off.