Ever since the iPhone appeared, the word “smart” has been used to describe devices that automatically adjust their functions in ways that supposedly benefit their users.

Beyond smartphones, we now have smart watches, smart thermostats and smart windows. The latter can modify their optical properties based on sunlight angles and interior radiant energy emission. There are even smart fabrics that change their thermal and moisture transfer characteristics based on the physical activity of the wearer.

From phone to fabrics, many of us now embrace the concept of making everything around us “smart.”

If that’s the case, why are the majority of existing boilers in North America still controlled using mechanical aquastats that provide a fixed range of water temperature? Is it smart to operate a boiler at a water temperature high enough to meet the building’s coldest day heating load, when it’s 55° F outside on a September afternoon?

I’ll answer my own question: No, it’s not smart, at least not according to how that word is being used in modern culture. But it’s simple and it’s traditional.

So, does simple and traditional trump smart? If you think it does, I challenge you to get rid of your smartphone and replace it with a flip phone — assuming you can still find one.

While you’re at it, get rid of your computer and go back to preparing letters, invoices and other business documents on a typewriter. After all, typewriters are pretty simple devices, especially the ones that don’t need electricity, and they were certainly traditional for many decades.

Reset is notrocket science

Aren’t we at a point where we should be controlling boilers, even those installed a couple of decades ago, using smart aquastats?

Unlike a typical aquastat, an outdoor reset controller calculates the necessary supply water temperature to a hydronic distribution system based on the ever-changing outdoor air temperature. The colder it gets outside, the higher the calculated supply water temperature, and vice versa.

This action can all be traced back to two basic concepts for how heating systems operate:

1.The rate of heat loss from a building is proportional to the difference between the inside and outside temperature.

2.The rate of heat output from any hydronic distribution system is approximately proportional to the difference between the supply water temperature and the room air temperature.

Put these concepts together mathematically and you get “cruise control” for the water temperature supplied to any hydronic heating distribution system, and that’s a smarter way to operate the system.

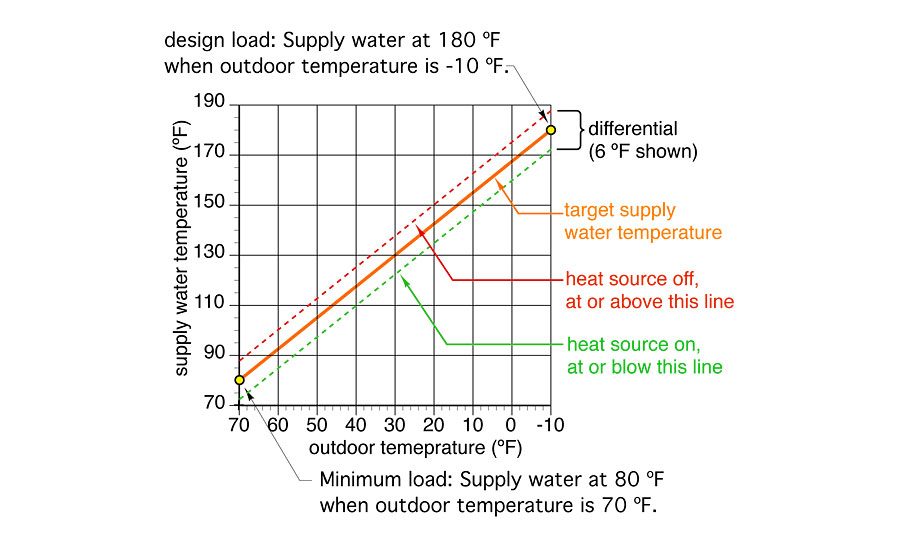

Figure 1shows a typical reset line for a fin-tube baseboard system. The orange sloping line shows the target supply water temperature required by the heat emitters to sustain a normal comfort temperature within a building over a range of outdoor temperatures.

In this case, the minimum load point shows a target supply water temperature of 80° at a corresponding outdoor temperature of 70°. The target supply water temperature has been set a few degrees above 70° to provide a hedge against a comfort complaint on a damp/windy day, when the owner wants to put a trickle of heat into the building, and thus expects the heat emitters to get slightly warm when the system is put into operation.

The design load condition shown in the upper right corner of Figure 1 indicates a target supply water temperature of 180° at a corresponding outdoor temperature of -10°; 180° is a typical supply water temperature for a fin-tube baseboard system under full design load conditions.

The orange “reset line” is used to find the target supply water temperature at all outdoor temperatures between the minimum load point and the design load point. For example, when the outdoor temperature is 30°, the reset line indicates a target supply water temperature of 130°.

The location of the minimal load point and the design load point can be adjusted over a wide range of temperatures on all modern outdoor reset controllers.

The outdoor reset controller turns the heat source on and off to maintain the water temperature leaving the heat source within a narrow range that’s centered on the target supply water temperature. For example, when it’s 30° outdoors and the target water temperature is 130°, the heat source might be turned on when its leaving water temperature is 127° or less, and turned off when its leaving water temperature climbs to 133° or higher.

This would correspond to a 6° differential that is centered on the current target temperature of 130° (e.g., the “on” condition is 3° below the target temperature and the “off” condition is 3° above the target temperature). This differential, which helps prevent the heat source from short-cycling, also is adjustable on most outdoor reset controllers.

Not a hard sell

The benefits of outdoor reset control are well-established. They include the following:

1.Outdoor reset control reduces fluctuation of indoor temperature. The water temperature supplied to the heat emitters is just high enough for the prevailing heating load. This provides very stable indoor temperature compared to less-sophisticated hydronic systems that deliver water to the heat emitters as if it were always the coldest day of winter.

Because outdoor reset control supplies water just hot enough to meet the current heating load, the distribution circulator(s) remains on most of the time. Flow through the distribution system stops only to prevent overheating when internal heat gains from sunlight, equipment and interior lighting are present.

2.The combination of near-continuous circulation and very gradual changes in water temperature minimizes expansion noises from the distribution piping and heat emitters. During a typical heating season, the piping and heat emitters in any hydronic system will experience thermal expansion movement. However, when outdoor reset control is used, the expansion movement takes place over hours, even days, compared to what might only be seconds in systems that simply turn the flow of hot water on and off.

3.Outdoor reset control has demonstrated its ability to reduce fuel consumption in hydronic heating systems. The savings are a combination of reduced heat loss from boilers, reduced heat loss from distribution piping and, in the case of condensing boilers, increased time in condensing mode operation. Conservative estimates of energy savings are in the range of 10% to 15%.

4.In systems where a heat source is controlled based on a fixed water temperature high enough to meet the maximum heating load, occupants can choose to set the thermostat to a high temperature, and open windows and doors to control overheating on all but the very coldest days.

Although this sounds like a foolish and wasteful means of controlling interior comfort, it’s done in rental properties where occupants don’t pay for their heat. However, if the supply water temperature to these spaces is regulated by outdoor reset control, it’s just warm enough to meet the heating load. Leave the windows closed or chill out!

A simple outdoor reset controller retails for about $150. Even in residential applications, it will likely save enough fuel to cover its installed cost within two to four years. That’s a payback most renewable energy system providers only wish they could offer. An outdoor reset controller is not as sexy as solar collectors, wind turbines or heat pumps, but it works, it’s pretty easy to install and its low installed cost is easy to justify.

Renewable resource

The largest application for outdoor reset is for controlling the water temperature produced by automatically fired boilers. However, a basic outdoor reset controller, the same unit that would be used for controlling an on/off boiler, can be very useful in systems supplied by renewable energy sources.

For example, it can be used to determine when a geothermal water-to-water heat pump should turn on based on the temperature of water in a buffer tank. Under partial load conditions, the outdoor reset controller allows the thermal storage tank to drop to lower temperatures before turning on the heat pump. That leads to lower condenser temperatures, which increase both the heating capacity and coefficient of performance of the heat pump. Same amount of heat delivered using less electrical energy. That’s smart …

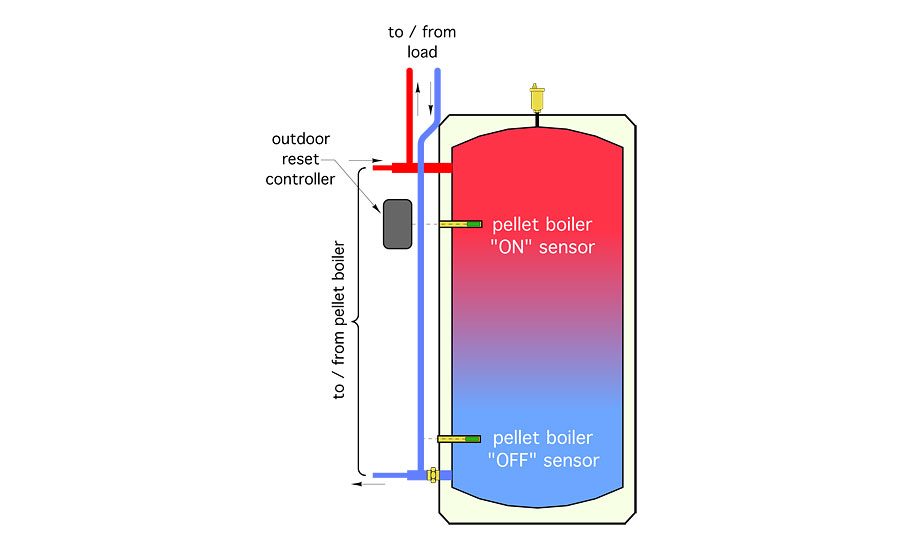

An outdoor reset controller also can provide the “go” signal for a pellet-fired boiler charging a thermal storage tank, as shown in Figure 2. The “stop” signal is provided by a temperature setpoint controller monitoring the lower temperature sensor in the tank. The latter is usually set to a relatively high temperature in the range of 170° to 180°.

By reducing the water temperature at which the pellet-fired boiler is fired on partial load days, the outdoor reset controller “stretches out” the useful temperature range of the tank. The wider the tank’s ∆T, the longer the boiler’s on-cycle and subsequent off-cycle — the key to high thermal efficiency and low emissions. That’s smart …

Finally, it’s important to understand that an outdoor reset controller is an operating control, not a safety control. Although it takes primary responsibility for turning the heat source on and off, it remains subservient to safety controls such as a manual reset high limit controller and a low-water cutoff. The normally open electrical contacts in an outdoor reset controller are typically wired in series with these safety controls. As such, the opening of any normally closed contact in a safety control will break the electrical circuit necessary to operate the heat source. This ensures a safe shutdown in the event of a malfunctioning or improperly set outdoor reset controller.

If your favorite temperature controller is a strap-on aquastat or a fixed temperature boiler high limit controller, it’s time to up your game to a basic outdoor reset controller. It may not be wireless, run the latest iOS or have an associated app, but it does provide enough smarts to significantly improve many hydronic systems compared to methods dating back to the 1940s.

This article is originally titled “Smarter than average” in the June 2016 print edition of Plumbing & Mechanical.