Over the years I've witnessed the ingenuity of North American hydronic heating manufacturers in creating products for perceived needs. I've seen products as unique as snap-on polymer covers for rusted fin-tube baseboard enclosures, bidirectional primary/secondary tees with internal baffles, pull-tie guns for attaching PEX tubing to welded wire reinforcing, and insulation board with knobs to hold the PEX tubing in place.

There's no doubt that manufacturers are always looking for opportunity and increased market share. That's exactly what they should do. It's part of what makes hydronics a truly dynamic field for those wanting to participate in cutting-edge design and product application.

This month I want to explore a couple of hardware needs that generate recurring interest in hydronic discussion circles. Both point to potential new products for enterprising manufacturers.

A New Paradigm

For decades our industry has sized boilers based on space heating loads. Domestic water heating was almost always considered an ancillary to space heating requirements.This is a result of what residential space heating loads used to be in comparison to domestic hot water loads. Forty years ago it was common to have a 150,000 Btu/hr. boiler in a modest house with a tankless coil capable of supplying 2 gallons per minute of domestic hot water. It was a relatively simple approach and usually worked just fine.

Although indirect water heaters have largely replaced tankless coils, the notion of sizing boilers for supposedly dominant space heating loads continues, even in larger residential systems having two or more boilers.

I've seen many schematics showing one boiler in a multiple boiler system piped so that it's the only one capable of heating domestic water. The other boilers sit disconnected from the DHW load, patiently waiting for a few hours of “design” heating load conditions. When a modest amount of boiler oversizing is used, there may never be a time when all boilers operate simultaneously. This scenario is not what's needed in most new upper-end homes.

The selection of luxury bathroom fixtures currently available to consumers is amazing in comparison to what most of us grew up with. Body spray bars, waterfall faucets, and rainspout showerheads all appeal to the human body's craving for maximum contact with warm water. The modern bath has been very successfully marketed as a luxurious escape from the cares of life. A tropical downpour showering experience available to you in Peoria during February. I could go on but trust you have the picture.

Regardless of how such bathrooms are sold, one thing's for certain - most of them have a huge appetite for hot water. That's where the hydronic heating industry should come into the picture and take charge of providing the copious quantities of DHW these baths require. It's a great opportunity for contractors and manufacturers alike, but it does require the right mind-set and the right equipment.

After comparing several options for providing high capacity DHW, I think the best solution is a multiple boiler system coupled to a high-capacity indirect water heater. This approach approximates the concept of instantaneously converting fuel into heat shortly before it's needed. It also adds a moderate amount of thermal mass to the picture (e.g., the water in the storage tank).

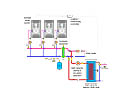

The latter allows minor loads such as a 10-second hand washing to be satisfied without lighting a burner. In “dump load” situations, such as rapidly filling a large tub, storage also allows DHW delivery rates faster than a purely instantaneous system of the same capacity. This approach is a hybrid between a purely instantaneous system and one that relies heavily on storage to meet sustained DHW demands. The hydronic piping concept is shown in Figure 1.

To The Numbers

So what exactly does the term high-capacity domestic water heating mean? Here's an example:Imagine your task is to deliver domestic hot water at 110 degrees F and a sustained flow rate of 15 gpm for as long as the owners want to operate their multiple luxury bath appliances. This is not an unrealistic load in many upper-end homes. In some cases, the master bath alone could create this load, never mind the other five bathrooms served by the same system.

Assuming a cold water temperature of 50 degrees F, this load requires a sustained heat input rate of:

Q = 500 x f x (Delta T) = 500 x 15 x (110-50) = 450,000 Btu/hr.

Where:

Q = required heat transfer rate (Btu/hr.)

f = water flow rate (in gpm)

Delta T = temperature rise of water (in degrees F)

While it exists, this DHW load could easily be three times greater than the design space heating load of a large home. Large enough to deplete an 80-gallon storage tank full of 140 degree F water in less than eight minutes. Once that storage is depleted, the ability to keep hot water flowing comes down to raw heat production and transfer rates. The boiler system has to generate it and the tank's heat exchanger has to transfer it to the domestic water. A bottleneck in either process can quickly turn the tropical downpour showering experience into the North Atlantic overboard survival challenge.

This is where many current indirect tanks fall short. Dissipating 500,000 to 800,000 Btu/hr. into the potable water with a maximum heat exchanger inlet temperature of 180 degrees F is beyond the capability of all but a very few currently available indirect tanks in sizes of 120 gallons or less. Simply put: Our industry needs more indirect tanks in sizes of 120 gallons and under that can handle at least 500,000 Btu/hr. of sustained heat transfer.

Such heat transfer rates require large heat exchange surfaces between the boiler water and potable water; significantly larger than what many tanks now provide. The designer's alternative is to use a generously sized external flat plate heat exchanger along with a bronze or stainless circulator, strainer and piping. This is almost certain to cost more than a larger heat exchanger within an indirect tank. I for one would welcome the latter, and readily specify such a product in many residential and commercial projects.

A Bigger Piece Of The Pie

We must keep reminding ourselves that the market for high-capacity water heating is not limited to homes where hydronic space heating has already been selected. That's the old way of thinking. The new mind-set is to look at almost any new or remodeled home with four or more bathrooms, especially those with high-end bath fixtures, and see it as a perfect fit for this concept.Explain to the owners how the DHW demand of their bath selections is likely to be far beyond that of a typical home. Emphasize how you can keep the warm water flowing from those trophy fixtures for as long as they desire. Folks who just dropped the price of a new BMW Roadster into their master bath need to hear this.

Now comes the best part. Once they understand the inevitable need for high-capacity water heating, show the owners how your hydronic approach to DHW can easily be expanded - now or in the future - to provide areas of floor heating, hydro-air heating, towel warmers, pool heating or even snowmelting. That's way beyond what dedicated direct-fired water heaters can do with higher efficiency and long system life as icing on the cake!

You probably won't be selling lots of snowmelting subsystems in Texas, but you probably could interest those folks in the ability to bring a 20,000- gallon pool up to 85 degrees overnight for a spontaneously arranged party the following day.

From Mega To Micro

The other product gap that needs filling pertains to systems having several heating microloads along with the associated boiler short-cycling. The availability of modulating boilers has certainly improved this situation, but operating the boiler at 20 percent of full firing rate is still not low enough when the load is a solitary towel warmer, panel radiator, or short radiant floor circuit. Microloads are common in residential bathrooms, especially during swing seasons when the main heat distribution system may not be operating. They're also very easy to create, intentionally or inadvertently, given the abundance of zoning products now available.The solution is a well-insulated and properly piped buffer tank. But where does one find such a product in the range of 20 to 60 gallons? Believe me, I've looked, and found very few options short of a modified electric water heater, which is far from ideal.

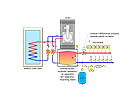

What's needed is a well-insulated (R10 minimum) steel tank with a pressure rating of 50 psi. The tank should have at least four properly placed 1 1/2-inch or even 2-inch piping connections to keep pressure drops and flow velocities very low. It should include a well for a temperature sensor and a top connection for air venting. A sloping bottom and drain valve could provide a “blow down” for sediment, which would settle inside the tank due to low flow velocities. The concept is shown in Figure 2.

In addition to thermal buffering, this tank would provide hydraulic isolation between a modern low-mass, high-flow resistance boiler and a rack of zone valves. It could also serve as an air separator, dirt separator and mixing chamber. It might even serve as an elevated stand for the boiler and support structure for a rack of zone valves or zone circulators and their associated controls. Think beyond a simple buffer tank to a multifunctional device.

If such a tank were constructed with closed cell foam insulation, it could also store chilled water used to supply cooling through air handlers as shown in Figure 3. Additional buffer tank volume could be achieved with modular stacked units. Prebuilt piping assemblies for manifolding multiple tanks could be offered as accessories.

Our industry needs some new tanks, specifically:

-

1. High-capacity, well-insulated indirect water heaters capable of sustained heat transfer rates of at least 500,000 Btu/hour using 180 degree F boiler water.

2. Well-insulated buffer tanks in the range of 20 to 60 gallons with appropriate piping connections and multifunction capabilities.