Those little screwdrivers have set many a control dial and DIP switch. Learning how to use those little screwdrivers is simple. Knowing exactly were to set each of those little dials and switches can be a bit more challenging and, at times, frustrating. Over the years, most us of us have spent a few hours in the truck getting to some remote jobsite just to exercise those little screwdrivers for a few seconds. On the drive home we’ve wondered if another trip will be necessary because the dials and switches might still not be in their “sweet spots” for that particular system.

Trickle Down

The days of dial and DIP-switch tweaking will soon pass. A new generation of control products is arriving that will allow us to set and reset them from a remote location using one or more types of digital communication.This comes as no surprise to readers who have worked with larger commercial or institutional HVAC systems in the last few years. Direct digital control (DDC) systems now allow the authorized support staff of such buildings to view and adjust hundreds of system-operating parameters from a PC either on- or off-site. In many cases, these systems control lighting, fire protection, elevators and security systems as well as HVAC.

Advances in digital technology including microprocessor capability, size, power requirements, and onboard memory have made it possible, both technically and economically, to scale DDC concepts down for smaller commercial and even residential systems. Communication between controllers, sensors and controlled devices is the key difference between the past and future of HVAC controls.

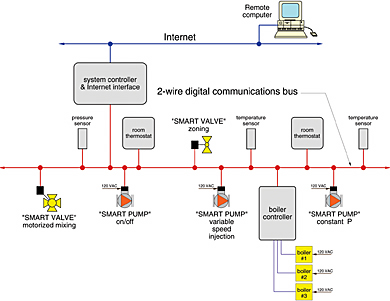

The concept of communicating control devices, as might be present in a future hydronic heating system, is shown in Figure 1.

The red horizontal line represents a communications “bus.” It usually consists of a two-wire pair running between the various devices in either a serial network or star network as shown in Figure 2. The latter has the advantage that a broken wire will only affect a given device and not stop communication over the entire network.

Some of you may be thinking, how can only two wires between devices allow all of them to communicate simultaneously? Herein lies the power of a high-speed digital network. Each device on the network has a unique digital address (e.g., a specific binary “call sign”). Any given device can only send or receive information when its address is active on the bus. At other times the information flows past without invoking any action. It’s the digital equivalent of speaking or listening when your name is called.

The speeds at which digital information can now flow through such a bus makes it possible for any given device on the network to receive or send information hundreds if not thousands of times each second. Given the response characteristics of most equipment used in HVAC systems, this is more than adequate, even if there are hundreds of devices sharing the same bus.

Keep in mind that every device on such a bus must be a “smart device”: It must have the embedded hardware and software necessary to listen and speak to the other devices. Full implementation of this concept thus requires manufacturers of devices such as motorized valves, pumps and heat sources to equip their hardware to operate on a network. Such smart devices are already on the market if you know where to look, and more are soon headed your way.

It’s also important to understand that the two-wire communications bus does not power the devices on the network. Operating power such as line voltage for circulators or 24 VAC for motorized valves is still necessary. The physical location of a given device on the network is usually irrelevant; it’s the digital address that counts. When a new device is attached to the network, the system controller automatically detects it and assigns it the necessary address for communications. It’s akin to how we can now “hot swap” USB or FireWire™ peripherals on our computer systems.

The system controller provides overall coordination for the communicating devices. In some systems, it also provides the gateway for Internet access to and from the control network. With the proper authorization, someone at any Internet-connected computer can access information such as the current settings, current operating conditions and even an operating log of how the system has performed over the last few days. They could also make changes if necessary — without the screwdriver or the truck. The system controller might even be configured to automatically send e-mails to a designated address if a fault is detected that requires servicing.

Speaking The Language

The communication “protocols” (e.g., the way digital data is sent, received and processed between devices on the network) are still sorting themselves out. At the upper end of the spectrum are protocols like the ASHRAE-developed BACnet®, which is often specified in larger building systems. Competing with it is the LONWorks® protocol, which is enjoying growing acceptance in smaller system applications.There are also proprietary communication protocols developed by specific manufacturers that don’t necessarily allow communication with other manufacturers’ devices. Herein lies the gamble for manufacturers. Do they try to establish market dominance with their own network protocol, or conform to an existing communications standard that allows interconnectivity between many existing and future devices? Remember Betamax® video and Commadore® computers? Both were very capable technologies in their day, but neither survived the inevitable market-driven shakeout.

Trade consortiums such as LONMark are working to quickly standardize the application of the LONWorks protocol among a wide range of manufacturers. In the very near future, look for home appliances such as clothes washers, televisions and even microwave ovens to all have the ability to communicate over a common network. Your heating system might even use your TV as a way of reporting a problem, even showing you were it’s located.

Another important advantage of communicating control devices is the elimination of redundant components such as power supplies, transformers, digital displays, keypads and sensors. Much of the processing capability now available in microprocessors is simply not being accessed using present day “multibox” site-built control systems. One processor, with the right programming and communications network, could easily manage a complex heating/cooling system. A fully communicating control network is also far less prone to control conflicts that can arise when each of several controllers is individually set.

Beyond Wires: How many of you have ever tallied the time and materials it takes to install low-voltage wiring in a present-day multiload hydronic system? In a large home you can go through thermostat cable by the mile, and time by the day. When you do add things up, be sure to add in a few hours for repairs after the drywallers shoot nails through some of your thermostat cables.

This aspect of system installation is also likely to change in the near future. Some HVAC controls will soon operate without wires. Technologies such as Bluetooth® already allow for easily configured wireless networks between computers and peripherals such as printers, keyboards, digital cameras, and even some cell phones. Such devices use short-range (presently up to about 10 meters) radio frequency communication. Wireless networks will soon become the norm for not only computers, but also building automation in general. Imagine thermostats and sensors you just peel and stick to a wall or pipe. Just think how much you’ll save on plastic zip ties.

Smart heating professionals are beginning to ramp up their knowledge on these technologies in anticipation of soon seeing them specified. If you want to learn more about them, I highly recommend some Web surfing. Type any of the terms such as LONWorks, Bluetooth, or BACnet into a search engine such as www.google.com, and be prepared for a few gigabytes of information.