Never having had a close encounter with a similar unit, I squatted down, grabbed hold of one leg, straightened my back, and pushed hard with both legs. That radiator didn't move one millimeter.

Now, I'm not exactly an Olympic lifter, but up until then most things had moved at least a little when given similar physical effort. In the end, it took four men, several planks and some mover's dollies to slowly coax that beast onto the truck. By now it must be the anchor for an aircraft carrier.

I came away thinking these behemoths were doomed to extinction. How could something so big, so unattractive and so heavy ever survive in the modern comfort heating market?

I'm not the only one to share this view. With all due respect for those who install and service these hydronic heavyweights, most people think of a radiator as a clunky, visually unappealing "thing" that must be aesthetically tolerated if one chooses not to freeze during winter.

Fortunately, this image is being rapidly transformed. Rather than being seen as an unavoidable necessity, modern panel radiators are turning the heads of discriminating owners as well as architects and interior designers.

For many North Americans the first encounter is one of disbelief.

"?hat's a radiator?"

This is usually followed by curious amazement, especially when warm water starts flowing through these modern meldings of technology and art. It doesn't take long to discover that these are not your father's radiators.

From Europe With Warmth

The market for European-style panel radiators continues to grow in North America. At least 11 companies now offer panel radiators to U.S. hydronic professionals. They range from compact towel warmers to customized units that can even be built to follow curved or angled walls.

Most manufacturers offer dozens of sizes, shapes and colors. Some models project less than 2 inches from the wall. Others squeeze into the narrow wall spaces often present in kitchens and bathrooms, places where conventional fin-tube baseboard is out of the question. Many panel radiators also can be "accessorized" with towel bars, mirrors, garment knobs and boot racks.

Fluted Panels

One type of panel radiator is manufactured from press-formed steel sheet. The forming process produces "flutes" or channels that join to a formed header at the top and bottom. The front and back sheets are welded together to create a sealed unit with lots of surface area yet relatively low water content. Steel fins are attached to the rear side of most panels of this type to enhance convective output. The completed assembly is pressure-tested, chemically cleaned, and finished with high-quality powder coat or enamel paint. Figure 1 shows some examples of fluted-panel radiators.

For high output requirements, two such panels are often connected back to back. Common side panels and a top grill make for a clean, simple appearance. Many radiators of this type also have an integral flow-regulating valve in the upper right corner. This valve can be fitted with a nonelectric thermostatic actuator to allow flow modulation through the radiator in response to room temperature.

Flat Pipes

Another common variety of panel radiator is built using flat steel tubes arranged in parallel and connected to headers at both ends. The tubes can be oriented horizontally or vertically. Units from 3-inches to 70-inches wide, and up to 29 1/2-feet. long can be manufactured allowing for hundreds of possible sizes. Most panels of this type also have several optional locations for piping connections.As with fluted panels, these panels have lots of surface area and low water content. A typical 18-inch by 6-foot. panel holds less than 2 gallons of water. With the proper controls, these low thermal mass panels can respond quickly to internal heat gains or desired changes in room temperature.

Horizontally oriented panels are commonly installed under windows or low on exterior walls. Panels with heights of 6 inches to 12 inches are installed as an alternative to fin-tube baseboard. They are equipped with steel fins on their rear side to enhance convection, and are well suited to counteracting drafts under large windows. Taller but narrower horizontal panels pack higher heat output into less horizontal wall space.

Vertical panels are great problem-solvers in tight confines, such as bathrooms and kitchens, where empty wall space is hard to come by. For example, a 12-inch wide, 7-foot tall panel has a heat output equivalent to about 7 1/2 feet of fin-tube baseboard, yet could easily fit on a narrow wall that's too small for other uses. (See Figure 2.)

Round Tubes

Still another variety of panel radiator is the tubular towel warmer. Again the concept is simple: A rack of horizontal steel tubes connected to vertical headers at each side. By leaving out a few tubes here and there, a space is created for a towel to be draped over the panels. Special standoff mounts hold the panel about 3 inches away from the wall so the towel has space to drop down behind it. Besides their obvious use in bathrooms, this type of radiator is great in entry foyers or mudrooms, where it quickly dries and warms coats, umbrellas and scarves. (See Figure 3.)

One manufacturer offers tubular towel warmers in sizes from 20 inches by 30 inches to 30 inches by 6 inches. Their heat output ranges from about 2,000 to 7,000 Btu/hr. at an average water temperature of 170 degrees F. The bottom of each header has 1/2-inch FPT connections. Most panels are mounted with a set of angle valves at the bottom of the headers. These nickel-plated brass valves allow flow through the panel to be regulated. Because they are equipped with unions, they also allow the panel to be isolated and removed from the wall if necessary for painting. Simple, durable and cozy -- take all three.

I Can't Believe It's A Radiator

Beyond the basic pressed-steel and tubular assemblies lies the realm of "designer radiators," a seemingly endless variety of shapes, colors and accessories guaranteed to surprise and amaze those who think of radiators as lowly 600-pound chunks of cast-iron. Perhaps even more amazing is the silent comfort these works of art deliver as warm water circulates through them. A few examples are shown in Figures 4-6.Beyond their basic function as heat emitters, panel radiators have been creatively integrated as architectural elements. They have been used as room dividers, coat racks, benches and even stair railings.

Some panel radiators can be ordered with inconspicuous electric heating elements. They can operate as stand-alone electric towel warmers, or as combination hydronic/electric units. This option allows for warm towels even if the boiler system or central heating plant is off during the summer.

For those who don't start every shopping jaunt examining price tags, towel warmers are even available with 24-karat gold plating. You can even get gold-plated valves to match. Just be careful with those pipe wrenches!

Piping Matters

Even the most stylish radiator can't deliver its anticipated thermal delights without proper piping. There are several possible approaches depending on the type of panel and the desired zoning control strategy.One approach is a simple series circuit. Although arguably the simplest to install, series circuits have significant limitations. Chief among them is the lack of individual heat output control from each radiator. Series circuits should only be considered for areas that can be controlled as a single zone. Avoid series circuits if one or more of the radiators is located in a room with high internal heat gains relative to the others. You can change the water temperature and you can change the flow rate, but the change always effects the entire series circuit rather than a single panel.

Another potential limitation of series circuits is high head loss. The individual head losses of all radiators, valves and interconnecting piping add together in a series circuit. Too many panels in series will lead to high head loss and low flow rates. The result will be cool panels near the end of the circuit.

Series circuits containing several radiators must also be designed to accommodate the drop in water temperature from one heat emitter to the next. In most cases, the size of downstream radiators must be increased to compensate for the lower water temperatures.

All things considered, the limitations imposed by series circuits typically outweigh their ease of installation.

Diverter Tees

Another piping option is a diverter tee system. This approach is well-suited for systems in which individual panel radiators will be zoned using thermostatic radiator valves (TRVs).A schematic of diverter tee piping is shown in Figure 7. The diverter tee is typically mounted as the return tee reconnecting the branch riser to the main. The tapered venturi in the tee creates a pressure differential that pulls water through the panel radiator as the TRV opens. As the room approaches the set comfort level, the TRV slowly closes off flow through the panel. It's a simple, silent and fully modulating approach to comfort control.

If TRVs are used on each panel, the distribution circulator must operate continuously during the heating season. This can be done several ways. If the system has a boiler reset control (which I highly recommend), the distribution circulator can usually be turned on by that control whenever the outdoor air drops below a preset warm weather shut-down temperature. A similar option is to use a separate setpoint control to turn on the circulator and allow the heat source to operate below a given outdoor temperature. A manual switch is also a possibility, although it is not automatic.

With nearly continuous circulation during the heating season, it's important to insulate the distribution piping with this type of system.

Bypass Valves

Another option commonly used in Europe and available in North America is an integral bypass valve. This valve, which resembles an "H," is mounted between the connections at the bottom of the radiator and the tubing supplying it. It contains an adjustable bypass port that provides a function similar to a diverter tee. As the radiator's TRV opens, some of the supply water flows into the radiator, while the remainder passes through the bypass port. When the TRV closes, all flow passes through the bypass. In effect the heated water does a U-turn just before entering the panel, and heads on down the line.Bypass valves make it possible to string several panel radiators together in what appears to be a simple series circuit, yet retain individual heat output control.

Some panels have an integral bypass chamber built into the lower portion of the panel that allows similar piping and control using TRVs.

To Each Its Own

My favorite method of piping a group of panel radiators is called a homerun system. Each radiator has its own supply and return tube that originates from a manifold station as shown in Figure 8.This approach offers some nice benefits. First, the size of the tubing runs to each panel seldom needs to be larger than 1/2-inch I.D. In many situations, 3/8-inch or even 1/4-inch nominal I.D. tubing can be used. The reason is that panel radiators can operate with a temperature drop of 30 to 40 degrees F. High temperature drops mean low flow rates. For example, a panel delivering 5,000 Btu/hr. with 170 degree F inlet and 130 degree F outlet water temperature only needs about 0.25 gpm of flow. This could easily be handled by a 1/4-inch I.D. (10 mm O.D.) tube.

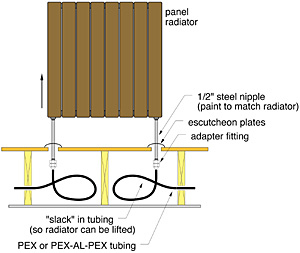

Small diameter PEX or PEX-AL-PEX tubing is easily routed through framing cavities. If you can pull an electrical cable from point A to point B, chances are you can also pull through a length of 3/8-inch PEX or PEX-AL-PEX tubing. This makes the homerun approach ideal for retrofit jobs where framing cavities usually have limited access. This is also a great place to use up those shorter segments of tubing left over from a radiant floor installation.

Homerun systems also deliver the same water temperature to each panel. The size of the panels doesn't have to be adjusted to compensate for supply temperature drops as it does with series- or diverter-type systems. If the supply water temperature is reset, all panels benefit equally.

Homerun systems also allow accurate heat output adjustment of each panel using the balancing valves on the manifold station. When individual room temperature control is desired, each radiator can be fitted with a TRV. This approach is ideal for situations where some rooms might experience high internal heat gains at various times of the day. Another alternative is to install low voltage valve actuators on the manifold and wire them to individual room thermostats. The end switches of the actuators are wired to operate the circulator and heat source when any one or more of the thermostats call for heat.

Some Other Pointers

Here are a few other things to keep in mind when working with panel radiators:- When installing long horizontal panels, allow for thermal expansion. A rule of thumb is to allow approximately 1/8-inch of expansion per foot of length for steel panels operating with water temperatures up to 180 degrees F. Be sure the attached piping can move without scrubbing against adjacent materials. Use escutcheon plates to cover oversized piping holes.

- Use piping details that allow the panel to be temporarily removed when walls need painting. Most panel radiator suppliers offer isolation valves with integral unions that make this a simple task. Another possibility is to allow some "slack" in the PEX or PEX-AL-PEX tubing supplying the panel that allows it to be lifted an inch or two to release it from its wall brackets. A suggested detail is shown in Figure 9.

- Most panel radiators are hung from steel wall clips. These clips should be attached to either solid framing or masonry. Do not support the panels on drywall. In many situations this requires blocking to be installed before the walls are closed in.

- Panel radiators release heat through convection and radiation. Panels with rear side fins will favor convection. Panels with large surface areas favor radiant output. Operating the panel at lower water temperatures increases the percentage of heat output by thermal radiation. It also increases the size of the panel needed for a given heat output.