When talking about disinfection, most people immediately think about chlorine. Chlorine has been around since the late-1800s, so it does have a great track record. But there are other ways to disinfect water. One advantageous alternative is ultraviolet light.

Light can disinfect? I'm kidding, right? Nope. Specific wavelengths of light do have disinfecting abilities. Sunlight is one of the best examples.

As you certainly know from the warm days of summer (and any accompanying sunburns), UV is one of the components of sunlight. It is this very component of sunlight that keeps microbes from ruling the Earth. If sunlight didn't keep at least some of the microbes on Earth in check, we'd all be covered in a gelatinous, gooey, microbial slime.

More refined sources of UV are adept at tackling even those organisms that chlorine has a difficult time coping with such as Giardia or Cryptosporidium. Take a look at why: Researchers have irradiated Cryptosporidia - the same organism that got 400,000 people sick and killed almost 100 people in 1993 in Milwaukee - with UV light and then injected rats with the irradiated organisms.

Interestingly enough, the rats did not get infected. Meanwhile, an average observer looking at the organisms through a microscope after irradiation would still see that the Cryptosporidia were still swimming around as if everything was OK.

Not so.

Inactivation

While the irradiated Crypto was alive, the rats did not get infected because the UV light had “inactivated” the organism.The irradiated organisms were not dead. The disinfecting action of UV light comes from its action on the DNA of the irradiated organism - specifically because of UV light's wavelength. This wavelength penetrates the cell wall of the organism and literally cuts the DNA, leaving the organisms sterile and unable to reproduce.

Normally, ingested Cryptosporidium would find a nice warm home in our intestines, and begin to reproduce very rapidly. The resulting invasion is what causes sometimes lethal dysentery in humans. Without being able to reproduce, however, microorganisms are unable to colonize environments in which they would otherwise thrive.

With any disinfectant, a dose parameter must be considered to achieve effective disinfection. In chlorine disinfection systems, a dose is a combination of a prescribed disinfectant concentration in milligrams per liter or parts per million, with a corresponding prescribed contact time. This combination yields some known amount of killing power with respect to some benchmark organism that is known to be difficult to kill (i.e., Giardia) when compared to the myriad of “garden variety” microbes in water.

In UV systems, dose is accounted for in the design of the unit. For a given bulb length or corresponding chamber size, plus a maximum flow rate, a threshold energy dose is achieved in the passing water.

This dose is generally stated in units of millijoules per square centimeter.

Maintenance

UV unit doses are also typically stated as the dose delivered at “end-of-life” for the lamp bulb. In other words, a particular unit might claim that it delivers 40 mJ/cm2 end-of-life. This means the bulb must be changed typically every 9,000 hours (approximately one year) because, over time, the intensity of the bulb is reduced.From a UV disinfection perspective, a drastic mistake is to base an assumption on whether a unit is still delivering the minimum dose by just a visual inspection of the lamp. After more than one year of continuous use, a UV lamp will still appear to be irradiating. Even at two years, it would appear to be irradiating properly. The human eye is not equipped to determine UV dose by appearance, and bulb changes should be a routine service event.

As a result, many UV units feature audible alarms or solenoid shut-offs that are linked to a UV sensor. These sensors can detect whether or not the proper UV dose is being received at a point in the water chamber.

In particular, a solenoid shut-off is a desirable feature since it physically prevents water (or even bacteria that can swim) from passing through the unit unirradiated if the unit is not delivering the proper minimum dose due to, say, a power outage.

Pretreatment

As a disinfectant, UV holds plenty of advantages - no disruption of chemical feed, no disinfection byproducts, no chemical handling, etc.However, light can be obscured by suspended solids or other components in the water. Any factor that could occlude the transmission of light, such as mineral scale formation or suspended solids, must be dealt with prior to reaching the UV unit. In other words, you are trying to reduce any factor that can shadow or protect microbes from exposure to UV light.

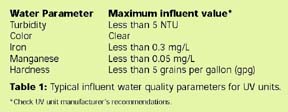

With almost every groundwater or surface water source, some amount of pretreatment is required in order to achieve the minimum water specifications in Table 1.

There are many elements of UV unit construction that are important. As with any technology, there are also some “bells and whistles” to be had.

First, in UV systems, the lamp bulb is contained inside a quartz-glass sleeve. The sleeve is a barrier between the warm bulb and the surrounding cooler water.

Since ultraviolet lamps are affected by temperature, it is important to insulate them from the water temperature with this sleeve. It is specifically made from quartz since UV is not transmitted through many other types of glass.

Also, some UV units have a series of bulbs on the exterior, while the water flows through the quartz tube. Either way, keeping the quartz clean is important for optimal transmission of UV. Some units even come with a wiping feature.

When evaluating a UV unit, one should consider the ease of bulb changes and other maintenance items. Service frequency (and resulting bulb sales) should also become a part of your company's service routine and may combine nicely with other water treatment service work.

Standards

Currently, there are several UV units on the market that are certified to the NSF/ANSI 55 Standard - Ultraviolet microbiological water treatment systems. There are two classifications for UV units per this standard: Class A and Class B.In short, Class A systems are designed to inactivate and/or remove microorganisms, including bacteria, viruses, Cryptosporidium and Giardia, when applied on microbiologically unsafe water. Class A systems are not intended to convert wastewater into potable water, nor are they intended to be used on water that has obvious or intentional contamination, such as raw sewage, for example, which would affect the original influent parameters for normal drinking water sources. Class A units must include UV-sensing ability and some form of alarm indicator.

Class B systems are those intended for applications on microbiologically safe sources, such as municipal water, which are tested and deemed acceptable for human consumption. In essence, Class B units are intended as a barrier to nuisance organisms.

UV already has shown great advantages in disinfection applications for a variety of application levels ranging from household use to industrial and municipal water supply systems. It is a technology you are certain to see more of in the future of water treatment.