If your firm wants to perform this specialty, you will need to acquire a professional, quality leak detection instrument, you'll need some training, and you will need to follow some prudent marketing and legal practices to avoid problems. So let's take the guesswork out of each of these issues.

Instruments

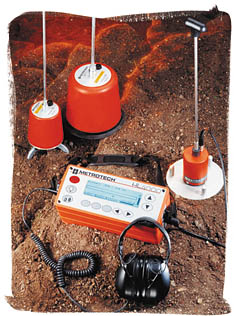

By and large, there are two groups of instruments: traditional analog detection equipment and spectrum-analyzing equipment. The latter instruments are particularly useful since the frequency range of pressurized water leaks, which is between 200 and 2,000 megahertz, can be analyzed. As an example, if the particular acoustic signature gives a peak value of 700 megahertz, then you can filter out all other frequencies within the aforementioned range and do searching based upon the strongest frequency.Higher-end systems also have some useful features, such as audio-muting, very high-quality microphones, frequency filters and higher-end displays, such as custom backlit LCD panels with an acoustic graphic interface for maximum value recording. As you might have guessed, these instruments rate very high on the gee-whiz scale.

Spectrum-analyzing instruments also tend to come with very high-quality microphones — but not always. To illustrate, I would rather employ an old-fashioned analog leak detection instrument with a very high-end microphone than a spectrum-analyzing instrument equipped with an inexpensive microphone.

Examples of manufacturers of very high-quality, spectrum-analyzing leak detection instruments are MetroTech, SubSurface Leak Detection, General Wire & Spring and Fuji. Examples of more traditional analog systems, more competitively priced systems with quality microphones are MyTana and Goldak.

Training

For whatever reason, I've found training in the use of leak detectors very difficult to find. Fisher is the only firm to my knowledge that produces a cassette tape of recordings of different leaks in water piping. LeakProbe is a relatively new firm that is now offering 10-day leak detection training in Sedona, Ariz. Also, Leakzone is a firm that sells all the correct plugs needed to help find leaks in pool filtration lines.Just as you may belong to the Quality Service Contractors, Contractors 2000 and Plumbers Success International groups, there are also professional associations for those who want to learn more about leak detection. The Underground Utility and Leak Locators Association was founded by leak detection firms as a nonprofit association for networking and training. Members work in the municipal, commercial, residential, industrial and swimming pool specialties.

Another means of not reinventing the wheel is acquiring a leak detection franchise via franchiser firms such as American Leak Detection, which offers franchises, training and marketing nationwide.

Procedures

When providing the service of leak detection, there is a specific flow that should be followed.First, a tech should ask the customer for a "symptom history," much as a doctor does. Has the customer noted any leak noises from under hard surfaces? Is a house pet uncharacteristically finding a sleeping spot on an otherwise cold concrete floor? Sometimes there are multiple symptoms. Since performing leak detection is part science, part equipment and a huge dose of spatial skills, collecting as many clues as possible is crucial.

Once a symptom history is narrowed down, your tech needs to discuss the limitations of the technology and procedure with the client. As an example, your staff should inform your clients that some leaks are extremely difficult to detect and locate. Also tell them that, while some leaks can be located with leak detection instruments alone, many cases will require gas injection into the system at an additional expense.

The reason for introducing a gas, such as air or nitrogen, into the system is because water leaking into water is fairly silent. To illustrate this, picture a garden hose turned on full blast and put it halfway into a bucket. Pretty noisy affair until the water level rises well above the end of the garden hose. Water silences itself. Pull the hose halfway out, and air makes the turbulence very noisy again. That is why almost all leak detection searches performed by professional leak detection franchises are done with nitrogen injection. Usually, it's nitrogen since it's inexpensive and available in high-pressure cylinders, although any gas will do.

Nitrogen is put into the system closest to where the leak is believed to be. This is first ascertained by touching contact microphone rods to exposed plumbing appurtenances, such as emergency water shutoffs, shower valves and piping.

Diagnostic clues can be found by turning off water heater inlet shutoffs, verifying that the shutoffs are working, then seeing if the leak sound stops. If it does, the leak may be in a hot water line, providing no cross connections are occurring. Some leaks can be so small in hot water lines that thermal expansion can cause intermittent leaks.

Once the best acoustic "signature value" is located, you can further hone in on the leak by tracing the pipes with radio frequency or running your microphones only over surfaces directly over the piping.

Once your tech has run through all the available diagnostic techniques and has reason to believe a specific area is the best area to excavate, more risks need to be discussed with the client. For example, a slab may contain post-tension cables used to reinforce the slab. Damaging or severing one of these can result in a costly lawsuit you’re sure to lose unless you use waiver forms and contracts with "concealed and unforeseen" circumstance clauses. Another caveat to discuss is how piping that penetrates through slabs and is not cushioned can propagate sound where the leak is not occurring. These are all just the risks and limitations associated with leak detection procedures.

Once this discussion has taken place, here's are few tips to keep in mind:

- It is good form and impressive to clients to use very thin, plastic film taped to walls to contain dust to the work area. Adhesive tapes can pull off paint or leave residue, so be sure to use painters' blue masking tape that has reduced-hold adhesives.

- Concrete floors are best prescored with diamond saws, whether this is accomplished with large walk-behind saws or skillsaws with 7.25-inch diameter diamond blades. Such prescoring can prevent concrete fractures or crack propagation from jackhammers.

- Once the area is excavated, sectional repairs can be performed. On copper tubing, this should be accomplished with high-temperature, silver-based brazing materials, required under codes such as the Uniform Plumbing Code. Using g-couplings or tin/antimony-based solder is poor form and under many codes illegal. Violating such procedure protocols is not only negligent but constitutes malpractice.

- Once a repair is completed, backfilling should be done with watery sand in the case of small excavations, or cementatious sand slurry in the case of larger excavations where slab support is needed.

To sum up, buying a scalpel — even the best you can buy — doesn't make you a brain surgeon. You need equipment and training. Thoroughly research your leak detection instrument options and, if you make the decision to add this specialty to your practice, put your staff through as much training as possible. Then establish a written procedure policy inclusive of scripts and printed risks, and limitations forms.

By carefully and thoughtfully following these steps, leak detection can be a profitable specialty addition to your firm.