Can Wet Heads be Watt Heads, too? Michael Ackmann, ex-president of the Radiant Panel Association, thinks so. His firm, New Century Comfort Systems Inc., Burlington, Ill., has specialized in hydronic radiant heat since the 1980s.

His initial thoughts on electric radiant heat was that it was too expensive to operate. However, four years ago, New Century won a job to install radiant in a garage/bedroom addition to a home that already had a radiant slab system.

Ackmann had no way to provide wet heat without exposing supply-and-return piping in the family room. No surprise, the homeowner didn't want to see any piping.

After reviewing his options, Ackmann decided to look into electric radiant since power to the addition was roughed in and could handle the proposed load.

Not only did the 240-volt cable system work great, the homeowner reported a modest rise in the electric bill and felt that the increased square footage of the addition was the main factor.

“We were pleasantly surprised at how easily the product installed and performed,” Ackmann says. “The ease of installation really sold us and we've never had a callback on that first system we installed in 2000.”

New Century now installs electric radiant heat in bathrooms, foyers and kitchens. With newer self-regulating systems hitting the market, the company can install electric systems under a variety of floor coverings, including carpet and wood.

A happy Wet Head and Watt Head, Ackmann installs each type in the best combination to fit the need of the particular job. For example, he recently installed a large hydronic snowmelt system to an existing home, but found the best way to handle the entry porches was to install electric cable.

“We embedded the cable in mortar and used a special covering over that, which meant the original porches did not have to be removed and replaced as they would have with hydronic snowmelt.”

Electric radiant is another tool in the bag to sell the radiant concept. “We've found this to be a whole new and wide-open market we could not have otherwise been able to tap into,” Ackmann explains. “It's a win-win story - we can sell more jobs, make more money and give our clients what they want, the comfort and efficiency of radiant heat at a price they can afford.”

Electric's Growth

While PM consistently writes about hydronic radiant heating installations, as Ackmann's experience shows, electric radiant systems are another popular way heating contractors can warm floors.“I want to think that for every hydronic radiant system that's installed, so is an electric system - only in smaller rooms,” says Larry Drake, executive director of the Radiant Panel Association, a group that includes most major hydronic and radiant heating manufacturers.

“I think that hydronic heating contractors should understand electric radiant in order to give homeowners a choice,” says Ada Cryer of Delta-Therm, Wauconda, Ill., and a current member of RPA's board.

Whether it's Btus or kilowatts, the market for radiant heat has grown steadily in the last decade. The RPA, for example, says hydronic tubing sales increased almost 11 percent last year to more than 213 million feet. That corresponds to approximately 55,500 homes. Meanwhile, it's estimated that another 60,000 projects this year will be heated with electricity.

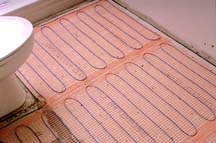

A Wet Head will find a variety of electric systems on the market with many meant to be covered over by a particular flooring choice. Some systems are just meant to take the chill off a tile surface, while others can serve as the primary heat source. While we may be simplifying the choices, the electric systems are available as cable that can be tied down and snaked around a room like you do with PEX; as thin cable in preformed mats or in mesh; elements embedded in plastic film; or as self-regulating mats and cables.

Free-form cables can easily wrap around any shape room and will cover a larger area than mats since the mats are fixed in width. Depending on heat-loss requirements, cable spacing can be tighter near exterior walls, again similar to PEX.

Still, you're going to be down on your hands and knees with cable. On the other hand, mats basically are cables attached at the factory to a square or rectangular matting material. While as simple to install as rolling out carpet, mats can't as easily be tailored to unique room requirements.

Again, we may be simplifying the procedures, but electric systems are typically controlled with a floor sensor and a room temperature thermostat. The floor sensor is usually installed in the grout layer between the cable and away from direct sunlight (similar to the sensor used to control hydronic snowmelt systems). When the floors dip below a temperature limit, heat flow is cycled on and off by a room temperature thermostat.

Some electric systems can control voltage in relation to room temperature. And certain systems can be made so the elements are self-regulating, meaning that they will limit heat output to a certain level.

As Ackmann and Drake contend, electric radiant makes a good choice for small rooms, particularly for remodeling situations. It's a bit more straight-forward to send electricity to a room than warm water. And most electric systems can be installed in a very thin layer of mortar on top of a subfloor, which adds a minimal increase to the finished floor height. Electric cable itself can be only 1/8 inch high, and typically embedded in 3/8 inch of mortar.

Electric Radiant Heating Systems

CaloriQue Ltd.www.calorique.com

Delta-Therm

www.delta-therm.com

D.K. Heating

www.dkheating.com

Easy Heat

www.easyheat.com

Electro Plastics Inc. (STEP Warmfloor)

www.warmfloor.com

FlexTherm Inc.

www.flextherm.com

Heatizon

www.heatizon.com

Infloor Heating Systems

www.infloor.com

NuHeat Industries Ltd.

www.nuheat.com

Orbit Manufacturing

www.orbitmfg.com

SSHC Inc.

www.sshcinc.com

WarmlyYours

www.warmlyyours.com

Warmup Inc.

www.warmup.net

Watts Radiant Inc.

www.wattsradiant.com

What Will They Think Of Next?

Here's an electric radiant heating product of a different sort - radiant windows. IQ Glass® has been for sale in Europe for the past 17 years and is now available in North America.The key to the windows is its double pane structure. The inner pane has a thin metal oxide coating that helps disperse heat equally, while the outer pane has a special coating that keeps heat inside while repelling cold air. Between the two panes is an inert gas that provides insulation.

Electrical connections, concealed within the window frames, heat the glass to a set temperature, detected by a sensor in the glass.

Once the temperature is reached, the heat is automatically cut off. When the surface of the glass drops below the set point, the sensor sends pulses of electricity back to the glass to provide heat.

Another feature allows the glass to turn completely opaque with just the flip of a switch.

For more information, contact IQ Glass Inc., 888/508-6711.

Electric Radiant Enhances Comfort At Yoga Retreat

“Where better than to put the heat into the floor, especially considering that it's the surface we spend all of our time on when we're in the yoga studio,” says Dee Hein, who runs Sadh Desha, a yoga retreat center on Orcas Island, about 20 miles off the coast of Northwest Washington.While Hein considered a hydronic system, she went with an electric system since the four-bedroom home she turned into the retreat three years ago didn't have a boiler. (The yoga studio was formerly the garage.)

The job called for 560 square feet of HeatWeave, an electric mat system made by Watts Radiant. Installation of the 220-volt system, and the cement that covered it, was a three-day job for contractor John Miller and one assistant.

“Not bad for first-time installers,” Miller says. Installing the mats themselves wasn't the time-consuming part. “Much of the time was spent mixing and applying a thin, protective coat of cement over the wire mat - we could have saved a lot of time by ordering a delivery of self-leveling cement, but we chose to do it ourselves.”

Watts Radiant engineer Tony Ledford, who designed the HeatWeave system for the yoga studio, said that a total of four equally sized mats were used to assure balanced heat.

“The system provides up to 40 Btus of heat drawing 12 watts per square foot,” Ledford explains. There are also two programmable thermostats, each of which has one 24-inch x 60-foot mat, and one 24-inch x 80-foot mat. Each mat is hard-wired to a T-stat. The system takes just 30 minutes to heat up.

“The radiant heat is so well-suited to yoga,” Hein adds. “People have commented about how cozy they feel. It's especially important for yoga to be practiced in a comfortable setting.”

Common Types of Electric Radiant Heating Systems

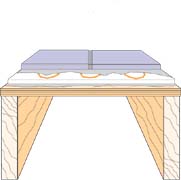

Embedded Cable, Mesh Or MatThe electric cable, mesh or mat is encapsulated by embedding it in a 1/8-inch to 2-inch mud bed or in thinset mortar on top of the subfloor as required by the National Electric Code. It is available as a low or line voltage for warming or heating. Higher output systems utilize wider spacing and require a thicker embedding layer. When only floor-warming is desired, the systems are usually controlled with a thermostat, often in combination with a floor sensor. Different system and embedding thickness allow for a variety of floor coverings. Check with manufacturer for limitations and recommendation regarding flooring goods.

Estimated Assembly R-value*: R-0.3 - R-1 depending on embedding layer

This type is formulated so that as the temperature of the mat or cable goes up, the resistance increases, which limits the heating output to a fixed temperature. Some may be embedded in a mortar layer or used directly (as recommended by the manufacturer) under a wide variety of floor coverings.

Estimated Assembly R-value*: R-0.3 - R-1 depending on embedding layer

With the film type product, elements are printed with a conductive ink and embedded in a film of plastic. Current products are line voltage. These systems have higher resistance to heat transfer than embedded systems since the heat must travel though an airspace and the subfloor. They must be installed with an air space.

Estimated Assembly R-value*: R-1.7 - R-2.2 pipe & 3/4-inch plywood only

* Assembly R-values are illustrative estimates only, and do not include the R-value of the floor coverings, which must be added to determine total system R-value. System design and installation should only be done by qualified professionals. Note: Insulation is usually required under heating systems.