Since bathrooms use more plumbing devices than kitchens, it stands to reason that this is where we have seen the most changes during the past 25 years. Before getting into the specific categories of products, let's stop here and talk about trends that affect all of them.

Finishes & Materials

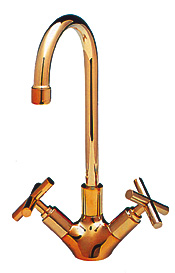

When the original College of Product Knowledge was published, you could count the number of common trim finishes on a couple of fingers - chrome and a little bit of polished brass. That was pretty much it. What we've seen happen since is an explosion of options that now include:

PVD has made a significant impact on the faucet industry by providing finishes that simulate polished brass and other metals that traditionally have been a challenge to maintain. PVD is the super hard titanium or zirconium coating that defies abrasion (frequently demonstrated at trade shows where you are invited to try your worst by scrubbing the surface of a faucet with steel wool or something equally nasty).

Like the styles of faucets and accessories today, their finishes have become trendy, now reflecting what's hot and what's sliding toward avocado status. Examples: a few years ago, manufacturers went crazy in the color department, offering an endless palette of options. The popularity of most shades has thankfully passed, with white and some off-whites being the main survivors. The latest in hot finishes seem to be the funky ones - oil-rubbed bronze, weathered brass and copper - the kind of thing that used to be featured in abandoned buildings. What's next? I'll let you know when I get back from the salvage yard.

It's funny how perceptions change. There was a time when an acrylic faucet handle was the premium choice over the ho-hum metal type. Today's audience views things just the opposite - plastic is cheap, metal is the quality choice. This is one of many examples of European influence that has so strongly affected our trends in recent years.

Shower Valves & Systems

With the advent of widespread codes requiring temperature protection in the shower, we have seen a huge swing to pressure balance and thermostatic valves. These are not new technologies - but what is new is their almost universal use today. Traditionally, Europeans have used thermostatic valving to meet the need of temperature safety, while Americans have used pressure balancing. While some would argue that the speed of response is the reason we have favored the latter, the lower price is probably closer to the real reason. But this is slowly changing. The price of thermostatic valves has been coming down, finding more market share in the mid-range bath today. Even with the wider use of these devices now, there is still a good deal of confusion over the difference between the two categories.Here's how I compare them: Pressure balance maintains a uniform temperature output by sensing and responding to relative pressure fluctuations between the hot and cold water supplies - thermostatic does it by sensing and responding to changes in the output temperature itself (whether due to pressure variations or any other cause, such as a gradual depletion in the hot water supply).

From the standpoint of controls, the requirement for temperature protection has been a blow to two-handle valve sets, since these are rarely equipped with either pressure balance or thermostatic devices. Among the shower valves that are so equipped, controls are either rotational (sometimes called "cycling") or single control. While single-control models provide volume regulation, not all rotational types do.

The Car Wash Comes Home

We used to think of a shower in strictly singular terms - one water delivery outlet attached to a shower arm. There are still lots of those, but increasingly we are seeing the shower become a system of outlets. Options can include one or more flanks of body showers, a hose-connected personal shower, sheet or drench delivery, steam, pulsating jets, and stereos. (Still to come is the drill press and trash compactor.) We are seeing an increase in the use of electronic controls for these systems, as well.Roman Tub Fittings

Manufacturers of whirlpool tubs have done a great job convincing a generation of folks that this is a "must have" component for any new or extensively renovated home. With the trend has come a major new category of trim to fill them - Roman tub fittings. Some of the first attempts at meeting this need were rather feeble in flow, with valves that took forever to fill these yawning canyons. (Back then, some manufacturers even suggested putting two sets of faucets side-by-side to meet the need.) By now, the faucet folks have gotten their products up to speed, most offering high-capacity valves that can fill large tubs much faster. Though this doesn't guarantee a particular flow rate, the common identifier of a high-capacity Roman tub set is 3/4 inch - referring to the nominal size of the inlet connections to the valves.Bidet Fittings

The faucet options for bidets have remained pretty much the same over the years. Over-rim models are typically slight variations on lavatory centerset designs, whereas rim-fill models are a bit like a widespread faucet without the spout. For the latter type, two additional devices are necessary - a vacuum breaker and diverter - and this is where there has been an innovation. While these were once two separate components, there is now a design in which they are combined into a cylindrical housing mounted on the rear ledge of the bidet. Rotating the handle at the top directs the water to either the rim or the spray.Lavatory Faucets -- Where Fashion Reversed A Trend

There was a time when it appeared that the two-handle faucet would become a dinosaur, due to the surging popularity of the single-control type. But the era of the high fashion bath came along just in time, and form began to retake some of the ground that had been gained by function. In other words, two-handle faucets - especially the widespread variety - just seemed to lend themselves better to decorative design. They may not be as convenient to use as the single-control type, but to a lot of folks, they just look better. While two-handle faucets continue to be viewed as the more decorative type, we are seeing increasing examples of more stylish single-control types today. The newest category of lavatory faucet is the wall-mounted type that is typically used with vessel-type basins (the type mounted atop a counter or vanity). Since these fixtures do not typically provide a conventional ledge, the faucet is mounted into the adjoining wall in modular fashion (valving often separate from spout). There are both single-control and two-handle versions of these fittings.Another different twist made necessary by the vessels-type of lavatory concerns the drain. Since there is no conventional deck-mounted faucet, there is no place for a conventional pop-up rod. This need is usually met in one of two ways:

(1) by use of a grid strainer with no stopper function (usually in public washrooms), or

(2) by use of a pop-up drain whose control is a lever accessed below the basin.