Protecting restroom users from scalding is critical in commercial applications. Though thermostatic mixing valves (TMVs) are a common way to regulate water temperature, they can add undue time and costs to one’s project. Historically, these valves were separate from the faucet, representing an additional component that needed to be specified, installed and maintained. From a practical standpoint, servicing the mixing valve is more difficult when it is located below the deck.

Plumbing engineers can now streamline restroom design and maintenance by selecting a faucet with a built-in thermostatic hot water temperature limiter. When the temperature limiter is incorporated directly into the faucet spout, the need for a separate TMV below-deck is eliminated.

This all-in-one scald protection is also faster to install and easier to service. This article explores how an integrated thermostatic hot water temperature limiter can improve commercial restroom faucet operation and reduce installation and lifecycle costs.

Protect restroom users

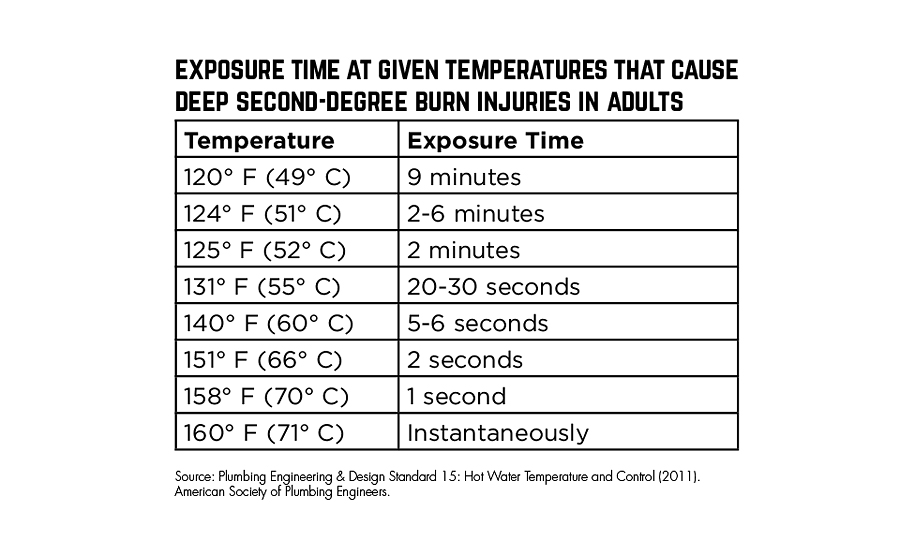

We have all experienced thermal shock — the unpleasant sensation of washing our hands when the water suddenly spikes to uncomfortable temperatures. But water that is too hot is more than a minor inconvenience — it’s actually unsafe and can cause irritation and serious burns within seconds. In fact, 34% of admissions to burn centers are due to scalds, with 8% of these incidences occurring in the workplace, according to a 2016 fact sheet from the American Burn Association.

It is a common misconception that water needs to be hot to eliminate germs while washing hands. The confusion might stem from the U.S. Food and Drug Administration’s (FDA) Food Code, which stipulates that water temperature in dishwashing equipment should be above 110° F. However, this guideline has no germicidal benefits, but rather is designed to ensure that water can loosen food residue from dishes. For hand washing sinks, the FDA recommends the use of a mixing valve to deliver water that is at

least 100°.

When examining the guidelines from the Centers for Disease Control and Prevention (CDC) and the World Health Organization (WHO) for best practices in effective hand washing, neither agency mentions water temperature. Both advise scrubbing hands for 20 seconds or longer with a mild soap. Additionally, research by microbiologists published in Food Service Technology agrees that vigorous hand washing is more effective than overly hot water to eliminate germs.

In fact, Amanda R. Carrico, a research professor at the Vanderbilt Institute for Energy and Environment, noted that hot water can undermine good hygiene by damaging skin, which makes it less resistant to bacteria. Excessively hot water may also discourage workers from washing their hands because of the resulting skin irritation.

Despite the evidence, many businesses still adhere to an outdated notion that hotter is better. This is true at the water heater itself, where 140° will kill Legionella bacteria, but this temperature is far too hot at the fixture’s point of use.

Ignoring the risk of scalding can leave an organization vulnerable to a lawsuit or workers’ compensation claim. An injured worker’s productivity may also suffer while he or she recovers from a burn injury. Even if water temperature limits are set within appropriate ranges, there can be sudden fluctuations in water temperature in the commercial restroom setting caused by a number of things, including:

-

Variations in water temperature discharge from the water heater;

-

Faulty thermostat settings on water heaters;

-

Malfunctioning temperature regulating valves; and

-

Water main breaks or other interruptions in the cold water supply.

When users experience unexpected changes in water temperature, they may be physically startled and splash water on the floor as they remove their hands. In addition to the potential scalding hazard that these fluctuations present, the puddled water on the floor increases the likelihood of a slip or fall.

Safety code overview

To protect users, ASSE 1070 (2015): Performance Requirements for Water Temperature Limiting Devices caps the maximum water temperature in public-use lavatories at 120°. ASSE 1070 is also referenced in other major building codes, including:

-

IPC (2012): Section 416.5 for Tempered Water for Public Hand Washing Facilities;

-

UPC (2012): Section 421.1: Limitation of Hot Water Temperature for Public Lavatories; and

-

ASPE Plumbing Engineering & Design Standard 15: Hot Water Temperature and Control.

ASSE 1070-certified devices are required by code to limit the water temperature delivered in public buildings such as offices, schools, hospitals, entertainment venues, airports, manufacturing facilities and stadiums. Scald protection should also be a priority for properties with populations that are vulnerable to temperature fluctuations, such as the young, elderly or individuals with health complications.

How thermostatic temperature limiters work

There are two common methods used to prevent scalding: delivering tempered water to the faucet and installing a thermostatic mixing valve (TMV) before each faucet. An ASSE 1070-certified thermostatic hot water temperature limiter automatically protects the user from scalding by stopping the hot water flow if the mixed water temperature to the user approaches 120°.

The process begins as hot water flows through the hot water chamber and combines with the cold water in the mixing chamber. This mixed water flows into the temperature-sensing chamber and across a thermostatic wax element. The wax reacts to changes in water temperature — expanding as the water temperature increases and contracting as the water temperature decreases.

As water approaches the safety shut-off temperature of 110°, the wax element expands and pushes the valve plunger closed, automatically shutting off the hot water. With the hot water turned off, the remaining cold water flows through the temperature-sensing chamber, which cools and contracts the wax element, eventually opening the valve plunger. The mixed water flow automatically resumes once the temperature drops to a safe level.

An integrated temperature limiter provides the same scald protection as traditional TMVs while eliminating the cost of installing and maintaining a separate external mixing valve.

The advantages of integrated anti-scald technology

Unlike conventional faucets, an integrated sensor-operated faucet with a built-in temperature limiter incorporates the battery, brass manifold, wax element and solenoid within the faucet spout. Faucets with an integrated temperature limiter offer several key advantages for architects, plumbing engineers, installers and building managers.

Simplified specifications: This integration saves plumbing engineers time because they don’t need to specify a separate TMV. Eliminating the faucet control box also frees up valuable space below the deck for other components.

Less clutter: Modern restroom design favors a clean, minimalist aesthetic. Using a faucet with an integral temperature limiter eliminates control box clutter under the deck for a more streamlined appearance. The simplified plumbing also gives designers additional latitude to include a small cabinet or vanity.

Faster installation: An integrated sensor-operated faucet is faster to install because the below-deck control box has been eliminated. Faucets install from above and contractors simply need to tighten the faucet and attach supply lines. Installers will avoid having to install components while on their knees in a tight space.

Reduced maintenance: Easy access to all faucet electronics can result in labor and cost savings. The above deck design prevents workers from having to crawl under the sink to perform repairs. Facility personnel can easily remove the faucet cover of a faucet with a built-in temperature limiter to access faucet internals for troubleshooting. There’s also no plumbing wrap that needs to be removed and reapplied whenever repairs are conducted.

Source: Plumbing Engineering & Design Stand 15: Hot Water Temperature and Control (2011). America Society of Plumbing Engineers.

Additional performance benefits

Scald protection and robust performance don’t need to be mutually exclusive. Faucets with an integrated temperature limiter should provide the same efficiency, sustainability and lifecycle benefits that are expected in modern restrooms, including the following.

Water savings: For example, an integrated faucet with a built-in temperature limiter can offer water savings over a standard 2.2 gallons per minute (gpm) faucet. These retrofits are a win-win for the environment and a building’s operating budget — switching from a 2.2 gpm faucet to a low-flow 0.5 gpm model can deliver immediate and ongoing savings of up to 80%.

Lead-free: For added protection, fixtures should be lead-free or compliant with NSF 372: Drinking Water System Components — Lead Content. Even though bathroom water is not intended for drinking, it is nonetheless a potable water source that may tempt users to refill drinking containers. Therefore, the NSF standard limits the amount of weighted lead in components that come in contact with water to less than 0.25% of the wetted surface area.

Hygiene: Hands-free faucets are an ideal way to promote hygiene and reduce the transmission of germs. To prevent ghost activation, the infrared signal should only respond to its own reflection and be unaffected by IR external such as sunlight, interior lighting and other sensor products.

Power options: Faucets with an integrated temperature limiter should also be equipped with the latest power options for long- lasting operation. Fewer battery changes will result in reduced downtime and maintenance costs. Certain AC power supplies are robust enough to simultaneously operate 10 to 15 faucets, which is ideal for large restrooms with multiple sinks.

The future of smart faucets

For architects, engineers, specifiers, facility managers and plumbers looking for dependable scald protection, an integrated thermostatic hot water temperature limiter provides a safe restroom lavatory experience. ASSE 1070 certified devices eliminate the added costs of having to specify, install and maintain separate TMVs. The next generation of smart faucets has truly arrived.

American Standard offers a line of NextGen Selectronic faucets that feature a simple, integrated ASSE 1070-certified thermostatic hot water temperature limiter. Unlike conventional sensor-operated faucets, the brass manifold, battery, wax element and solenoid of SmarTherm NextGen faucets are contained within the faucet spout, eliminating the need for a separate control box and TMV below the deck. The patent-pending touchless faucet streamlines installation because only the water connections are made under the sink. For more information, please visit bit.ly/Selectronic.