Mixing elements of modern water-heating technology and manufacturing efficiency with corporate and social culture, Navien in October hosted its first-ever trip to the Republic of Korea for North American customers. U.S. and Canadian distribution channel partners were accompanied on the trip by Navien executives, including North American CEO Scott Lee.

“The trip to our South Korean headquarters and factory with our wholesale and contractor partners allowed us to express our gratitude for their business,” Lee said. “Many people in the U.S. and Canada know Navien for our water heaters, but they do not know that we are a world leader in the boiler industry. The factory visit allowed us to show our customers how we ensure that quality is the key factor throughout our manufacturing of both boilers and water heaters. I am pleased with the customer relationships that we cemented on the trip.”

Some customers on the trip say they have sold or installed Navien’s tankless products since 2008. The mix of products they sell varies by geography with Canadian wholesalers tending to sell more wall-hung boilers and their U.S. counterparts selling a larger proportion of tankless water heaters.

“We’ve sold Navien products for the eight years since they came to the U.S.; we’ve been with them from the beginning,” said Kyle Cline, director of plumbing sales and branch operations for Oklahoma City-based Locke Supply Co. He adds that Locke’s mix of Navien sales is 95% tankless water heaters and 5% combi-units.

Peoria, Illinois-based Connor Co. has sold Navien products since 2009, General Manager Nick Lavin said.

“We sell a good mix, especially combi-units and tankless water heaters,” he said. “We’re starting to sell more and more wall-hung boilers. That market has started to grow for us.”

Loyal customers

Grover Martin of Greenville, South Carolina-based ProSource Supply said his company pioneered Navien tankless water heater sales in South Carolina’s upstate region starting in 2008.

“All Navien tankless units feature condensing technology now, but we sold them previously, as well,” he said. “Once we found out that condensing technology makes it easier for the contractor, we focused on Navien. What makes it easier for the contractor is piping the units with PVC pipe instead of stainless steel. Also, the efficiency ratings are so much higher now. They are 98% efficient where the old-style tankless units were in the higher 80% range.”

Martin noted that his company today sells tankless water heaters through its five showrooms as well as over the wholesale counter due to the training Navien provides his employees. His wife, Tonya Martin, manages the showrooms and accompanied him on the trip.

“All our showroom people ask our customers about how much hot water they use with body showers, whirlpools, and other bath and kitchen products,” Grover Martin said. “Several people from our company have attended Navien’s training program so they’re better educated on how to use Navien products in solving customers’ problems.”

Adam Grymberg of Girard, Ohio-based Adam-Eve Plumbing, participated in the trip, said he was not a proponent of tankless water heaters until Navien regional sales manager Doug Crogan asked him to install one in his house about six years ago.

“Then I saw how well it could work with the stainless steel heat exchanger and using PVC pipe for venting,” Grymberg said. “Deposits in the water don’t build up on the stainless steel heat exchanger. The design keeps the heat in the unit. This improves its efficiency, which is very high.”

Adding to his loyalty is the support he receives from Navien’s customer service representatives, he said.

“They always accommodate me when I am with a customer,” Grymberg said. “That’s a big deal if you’re in the service business.”

New about Navien

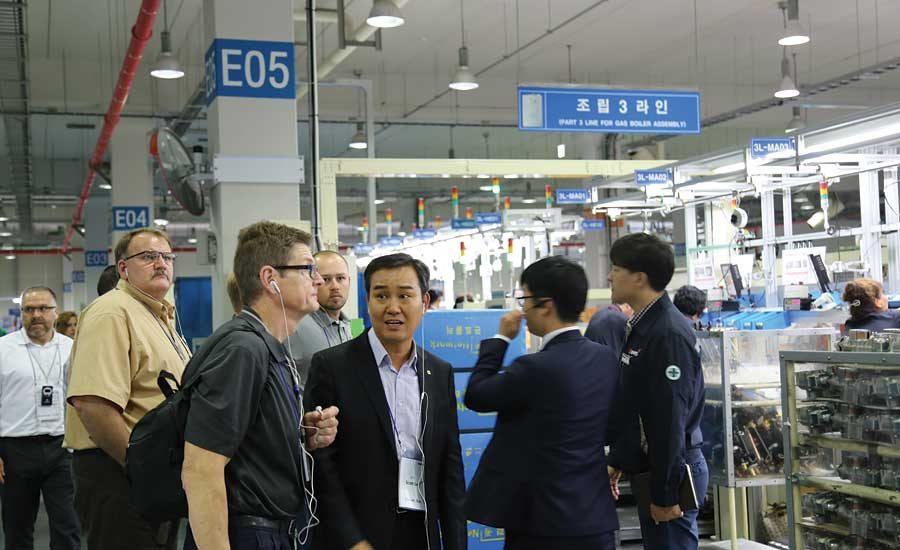

Navien’s customers say the trip taught them something new about the manufacturer, despite their long-term relationships. On Oct. 18, 2016, they toured the manufacturing and distribution facility in Seotan, South Korea.

“I was extremely impressed with the quality control process and testing that’s done,” Grymberg said. “Seeing this made me feel even better about installing these products for my customers. That’s a huge plus for me.”

Cline added: “From a technical standpoint, I didn’t realize so many components were produced in-house — the circuit board for the tankless units, for example. I just assumed a lot of the components were outsourced.”

The variety of products Lavin saw on the factory tour made an impression on him, as well.

“The big thing I took away is how big Navien’s market is outside the U.S. and how long it has been in the heating industry,” he said. “Then there are the products we haven’t seen yet in the U.S., such as a forced-air ventilator to improve air quality and a combined heat and power system that creates its own electricity with a Stirling engine. These products are a testament to how much engineering Navien has outside the U.S. market.”

The wholesalers remarked on the automated warehouse, where robots pick orders from inventory on the shelves.

“It was great to see the amount of inventory Navien keeps in its distribution facility and how quickly they can get product to us even though the factory is far away,” Lavin said. “Just the efficiency of it impressed me. It’s a nonstop process of pulling product from shelves that are completely full.”

“The efficiencies were amazing with little potential to make mistakes with machines doing all the work,” Martin said.

The trip was the first time any of the attendees had visited South Korea, save for the Navien employees. Customers received a broad sampling of Korean culture with visits to a folk village, a Buddhist temple and a Nanta comedy performance, as well as, to a Korean BBQ restaurant and karaoke bar. A side trip gave them the opportunity to visit the Demilitarized Zone that separates North and South Korea.

“We thoroughly enjoyed our experience,” Martin said. “I was struck by the Koreans’ work ethic and pride in what they do.”

“Navien definitely gave us a good mix of history and the future,” Lavin added. “They also showed us how dedicated they are to growing their business in the U.S. and what they are doing to get there.”

This article was originally titled “Quality time with customers” in the January 2017 print edition of Plumbing & Mechanical.